Introduction to Black Twisted Annealed Wire

The Black Twisted Annealed Wire is a versatile and robust solution designed for a wide range of industrial and construction applications. Manufactured by Dingzhou Lanye Metal Products Co., Ltd., this wire is engineered to provide exceptional strength, flexibility, and durability. Its unique properties make it an ideal choice for tasks such as binding, baling, and structural reinforcement. This article explores the features, advantages, technical specifications, and applications of this high-quality wire, along with insights into the company's expertise and commitment to customer satisfaction.

Key Features of Black Twisted Annealed Wire

The Black Twisted Annealed Wire is crafted from low-carbon steel, which ensures a balance of strength and malleability. This material choice allows the wire to maintain its structural integrity while remaining easy to manipulate during installation. One of its standout features is its twisted design, which enhances its tensile strength and resistance to deformation. The wire's black color is achieved through a specialized annealing process, which not only improves its aesthetic appeal but also provides additional protection against corrosion.

Another notable feature is its adaptability to various applications. Whether used for securing materials in construction, bundling items in industrial settings, or reinforcing structures in landscaping projects, this wire delivers consistent performance. Its annealed finish ensures that the wire remains flexible, reducing the risk of breakage during use. Additionally, the wire is available in multiple configurations, including coil wire, spool wire, and big package wire, catering to different storage and handling needs.

Advantages of Using Black Twisted Annealed Wire

Choosing Black Twisted Annealed Wire offers numerous benefits that make it a preferred choice in various industries. One of the primary advantages is its durability. The wire's low-carbon steel composition, combined with its twisted structure, ensures it can withstand heavy loads and harsh environmental conditions. This makes it ideal for applications where reliability is critical, such as in construction and infrastructure projects.

Another significant advantage is its corrosion resistance. The black annealing process not only enhances the wire's appearance but also creates a protective layer that prevents rust and oxidation. This is particularly beneficial in outdoor applications or environments with high humidity. Furthermore, the wire's flexibility allows it to conform to irregular shapes without compromising its structural integrity, making it easier to handle and install.

From a cost-effectiveness standpoint, Black Twisted Annealed Wire offers excellent value for money. Its long lifespan and minimal maintenance requirements reduce the need for frequent replacements, saving both time and resources. Additionally, the company provides free samples and consultation services, enabling customers to evaluate the product before making a purchase. This commitment to customer satisfaction is a testament to the company's dedication to quality and service.

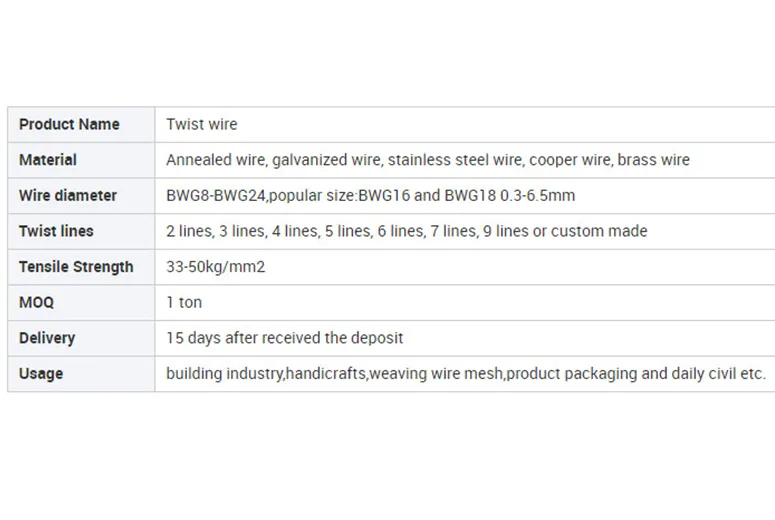

Technical Specifications of Black Twisted Annealed Wire

The Black Twisted Annealed Wire is designed to meet rigorous industry standards, ensuring optimal performance in diverse applications. Below is a detailed table outlining the key technical specifications of the product:

| Parameter | Specification |

|---|---|

| Material | Low-carbon steel |

| Finish | Black annealed |

| Twist Type | Twisted (3-5 wires) |

| Diameter | Varies by application (e.g., 1.0mm, 1.2mm, 1.6mm) |

| Tensile Strength | Approx. 350-450 MPa |

| Flexibility | High, suitable for bending and shaping |

| Corrosion Resistance | Enhanced by black annealing process |

| Surface Treatment | Smooth and uniform finish |

| Available Configurations | Coil wire, spool wire, big package wire |

These specifications highlight the wire's ability to perform under demanding conditions while maintaining its structural properties. The twisted design ensures even distribution of stress, reducing the risk of failure during use. Additionally, the wire's surface treatment guarantees a consistent quality that meets international standards.

Application Scenarios for Black Twisted Annealed Wire

The Black Twisted Annealed Wire is widely used across various industries due to its versatility and reliability. In the construction industry, it is commonly employed as a tie wire for securing rebar in concrete structures. Its high tensile strength ensures that the rebar remains in place during the curing process, contributing to the overall stability of the structure.

In industrial settings, the wire is used for bundling and securing materials such as cables, pipes, and machinery components. Its flexibility allows it to conform to irregular shapes, making it ideal for applications where traditional binding methods may not be suitable. Additionally, the wire's corrosion resistance makes it a preferred choice for outdoor use, such as in landscaping and agricultural projects.

The Black Twisted Annealed Wire is also utilized in home and DIY projects. Whether it's for hanging plants, securing garden tools, or creating custom storage solutions, this wire offers a durable and cost-effective alternative to traditional binding materials. Its black color blends seamlessly with most environments, making it a popular choice for both functional and aesthetic applications.

About Dingzhou Lanye Metal Products Co., Ltd.

Dingzhou Lanye Metal Products Co., Ltd. is a leading manufacturer of high-quality annealed wire and wire mesh products. With over 15 years of experience in the industry, the company has established itself as a trusted supplier to clients worldwide. Their commitment to innovation, quality, and customer service has earned them a reputation for delivering reliable solutions that meet the evolving needs of various sectors.

At the core of Dingzhou Lanye's success is its team of qualified engineers and technicians, who are dedicated to ensuring that every product meets the highest standards. The company invests heavily in advanced manufacturing technologies and rigorous quality control processes to maintain consistency and excellence in its offerings. This focus on quality is reflected in the Black Twisted Annealed Wire, which is internationally accredited and recognized for its superior performance.

Dingzhou Lanye is also committed to sustainability and environmental responsibility. The company adheres to strict guidelines to minimize waste and reduce its carbon footprint, ensuring that its operations align with global standards. By prioritizing eco-friendly practices, Dingzhou Lanye not only contributes to the preservation of natural resources but also meets the growing demand for sustainable solutions in the industry.

Frequently Asked Questions (FAQs)

Dingzhou Lanye Metal Products Co., Ltd. has compiled a list of frequently asked questions to provide customers with essential information about their products and services:

- Q1: Are you a manufacturer?

A: Yes, we are a steel wire and wire mesh manufacturer with over 15 years of experience. We have professional technicians and testing teams to ensure product quality. - Q2: Do you have advantages in steel wire or wire mesh quality and price?

A: Our wire and wire mesh have world-class quality and are internationally accredited. Our wire prices are in the middle range in China, offering excellent value for money. - Q3: What is the average lead time?

A: For samples, the lead time is about 7 days. For mass production, it is 20-40 days after receiving the deposit payment. We strive to accommodate your needs. - Q4: Do you have a minimum order quantity (MOQ)?

A: Yes, we require an ongoing MOQ for international orders. The MOQ varies by product; please contact us for specific details. - Q5: What are your payment terms?

A: We prefer T/T 30% as a down payment, with the balance against the B/L copy. We also accept 100% LC at sight. - Q6: What are the characteristics of doing business with you?

A: We never cheat customers! We provide quality products, excellent service, competitive prices, and prompt delivery. We look forward to greater cooperation with overseas customers based on mutual benefits.

Conclusion

The Black Twisted Annealed Wire is a versatile, durable, and cost-effective solution for a wide range of applications. Its unique combination of strength, flexibility, and corrosion resistance makes it an ideal choice for industries such as construction, manufacturing, and landscaping. Manufactured by Dingzhou Lanye Metal Products Co., Ltd., this product exemplifies the company's commitment to quality, innovation, and customer satisfaction.

By choosing Black Twisted Annealed Wire, customers can benefit from a reliable product that meets international standards and delivers exceptional performance. With a focus on sustainability and continuous improvement, Dingzhou Lanye is well-positioned to meet the evolving needs of the global market. Whether you are a professional in the construction industry or a DIY enthusiast, this wire offers a practical and durable solution for your binding and reinforcement needs.

Authoritative Citations

The information provided in this article is supported by industry standards and research from reputable sources. For further details on the properties and applications of steel wire, refer to the following authoritative resources:

- National Institute of Standards and Technology (NIST) – Provides comprehensive guidelines on material specifications and testing procedures for steel products.

- ASTM International – Offers standards for the mechanical properties and performance of steel wires used in construction and industrial applications.

For more information on the Black Twisted Annealed Wire and its applications, visit the official website of Dingzhou Lanye Metal Products Co., Ltd..