The Evolution of High-Security Fencing: Understanding Blade Barbed Wire in Modern Perimeters

In an increasingly complex global landscape, the demand for robust and impenetrable perimeter security solutions has surged across governmental, commercial, and private sectors. Among the myriad of options available, the blade barbed wire system stands as a formidable deterrent, evolving significantly from traditional barbed wire to a sophisticated security barrier. This advanced form of security fencing, commonly known as razor wire or concertina wire, incorporates sharp blades strategically positioned to prevent unauthorized access, offering superior protective capabilities compared to its predecessors. The industry has witnessed a paradigm shift, moving beyond simple physical barriers to integrated security systems that combine robust materials with ingenious design for maximum effectiveness. Modern installations frequently incorporate elements such as electrifying features, surveillance integration, and advanced deployment methods to create multi-layered defenses. This strategic deployment is driven by increasing threats ranging from industrial espionage to critical infrastructure protection, demanding solutions that are not only physically intimidating but also technologically sound and compliant with international security standards. The trend indicates a continuous innovation in materials science and engineering to enhance corrosion resistance, longevity, and ease of installation, while simultaneously maximizing deterrent effect. Furthermore, the global market for high-security fencing is experiencing consistent growth, fueled by geopolitical factors, expanding industrial complexes, and heightened awareness regarding asset protection.

The core appeal of blade barbed wire lies in its unparalleled deterrent capacity, which is critical for securing sensitive sites such as military bases, correctional facilities, power plants, and high-value commercial properties. Unlike standard barbed wire, which primarily relies on pointed barbs, razor wire features razor-sharp blades that inflict serious injury upon attempted breaches, making it exceedingly difficult to cut, climb over, or bypass. This inherent characteristic significantly elevates the security profile of any perimeter, forcing potential intruders to reconsider their attempts. Manufacturers are increasingly focusing on developing variants like flat wrap razor wire and welded razor wire mesh to cater to diverse aesthetic and functional requirements, without compromising the security integrity. These innovations allow for integration into existing fence lines or as standalone barriers, providing flexible yet robust security layers. The material science behind these developments is also crucial, with a strong emphasis on high-tensile steel and advanced galvanization processes to ensure longevity and resistance against harsh environmental conditions, including extreme temperatures and corrosive elements. This ensures that the security infrastructure remains effective and maintenance-free for extended periods, reducing the total cost of ownership for end-users. The rising adoption rates across various sectors underscore the recognition of razor wire fence as a cost-effective and highly reliable solution for comprehensive perimeter security, offering peace of mind to stakeholders.

Manufacturing Precision: The Advanced Production of Blade Barbed Wire

The production of high-quality blade barbed wire is a meticulous process that combines advanced material selection with sophisticated manufacturing techniques, ensuring a product that meets stringent security and durability standards. The initial stage involves selecting premium-grade steel, typically high-carbon steel or stainless steel, which undergoes a rigorous wire drawing process to achieve the desired tensile strength and diameter for the core wire. This core wire forms the backbone of the razor wire, providing the structural integrity necessary to withstand substantial force. Simultaneously, large coils of steel strips are fed into specialized stamping machines. These machines are equipped with precision dies that punch and flatten the steel into the distinctive razor-sharp blades that characterize razor wire. The geometry of these blades is critical, designed to maximize deterrent effect while ensuring structural resilience. Following the stamping process, the individual blades or blade segments are then cold-formed and crimped onto the core wire using automated machinery. This crimping process ensures a secure and permanent attachment, preventing blades from detaching or rotating, which is vital for maintaining the barrier's effectiveness. The efficiency and precision of this stage determine the consistent sharpness and spacing of the blades along the wire.

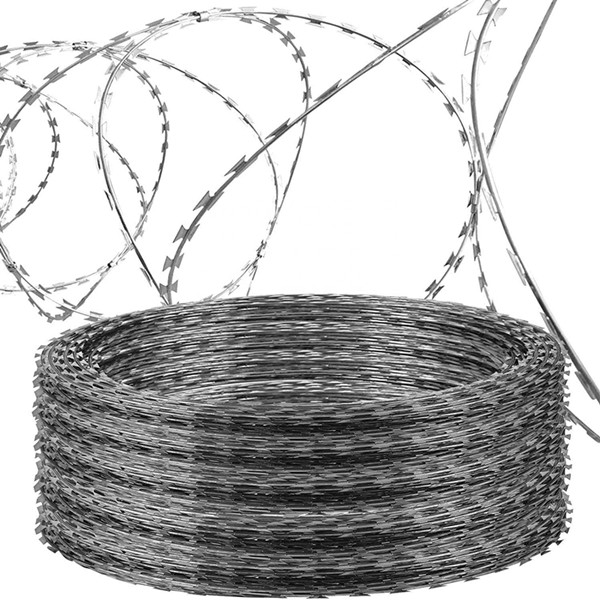

Image 1: Advanced manufacturing of Concertina Razor Ribbon Barbed Wire.

Post-assembly, the entire razor wire undergoes a critical surface treatment, primarily hot-dip galvanization or powder coating, to provide exceptional corrosion resistance. Hot-dip galvanization involves immersing the wire in molten zinc, creating a metallurgical bond that offers superior protection against rust and environmental degradation. For stainless steel variants, the inherent corrosion resistance negates the need for galvanization, though passivation treatments may be applied to enhance surface inertness. Quality control is integrated at every stage, with strict adherence to international standards such as ISO 9001 for quality management and ASTM A123 for zinc coatings. Products are regularly subjected to salt spray tests (ASTM B117), tensile strength tests, and blade sharpness evaluations to ensure consistent performance and longevity. The expected service life of galvanized concertina wire typically ranges from 15 to 25 years, while stainless steel options can exceed 30 years, depending on environmental conditions. These rigorous inspection standards ensure that each roll of razor wire roll or concertina coil performs optimally in its intended application. Applicable industries leveraging these durable solutions include military and defense, correctional facilities, critical infrastructure (such as power grids and water treatment plants), borders, and high-security industrial compounds. The anti-corrosion properties are particularly advantageous in coastal areas or regions with high humidity, significantly reducing maintenance costs and ensuring continuous security efficacy.

Technical Parameters and Specifications of Blade Barbed Wire Systems

Understanding the technical parameters of blade barbed wire is crucial for effective deployment and ensuring optimal security performance. These parameters dictate the barrier's strength, durability, and effectiveness as a deterrent. The core wire diameter, typically ranging from 2.5mm to 3.0mm, determines the tensile strength of the wire, with higher diameters indicating greater resistance to cutting and bending. Blade thickness, usually between 0.5mm and 0.6mm, contributes to the sharpness and structural integrity of the blades, ensuring they remain effective over time. The blade length and barb spacing are also critical, influencing the density of the deterrent. Common blade types include BTO-22 (Blade Type Obstacle 22mm) and CBT-65 (Concertina Barbed Tape 65mm), each offering a distinct level of aggression and deterrent capability. Coil diameter, available in various sizes from 450mm to 960mm, affects the height and volume of the barrier when deployed, directly correlating to the difficulty of penetration. For instance, a larger concertina coil diameter creates a more imposing and difficult barrier to overcome. The material composition, primarily galvanized steel (ranging from 60g/m² to 275g/m² zinc coating for hot-dip galvanized variants) or stainless steel (SS304, SS316), determines the longevity and corrosion resistance, which are paramount for outdoor installations in diverse climatic conditions.

Image 2: Illustrating the precision of Cross-Type Razor Blade Wire.

The deployment length of a razor wire roll is another vital specification, indicating how many linear meters a single coil can cover once expanded. While a concertina wire coil might be 600mm in diameter when compressed, its effective deployment length can be between 8 to 15 meters, depending on the number of clips and desired density. The number of clips per coil, which typically varies from 3 to 5 clips per spiral for single coil razor wire and 5 to 7 clips for cross-type concertina wire, influences the integrity and entanglement potential of the barrier. More clips mean a denser, more robust barrier that is harder to bypass. Understanding these technical nuances allows security professionals to select the most appropriate razor wire fence configuration for specific threats and environmental challenges. For instance, a site requiring maximum anti-climb capabilities might opt for a larger coil diameter with more clips and a specific blade type like CBT-65, whereas a general deterrent might utilize BTO-22 with standard coil sizes. The data presented in the table below provides a comprehensive overview of typical specifications that inform product selection and deployment strategies for various high-security applications, from military perimeter defenses to correctional facilities and critical infrastructure protection.

| Parameter | Specification Range | Industry Standard (Example) |

|---|---|---|

| Material | High Carbon Steel / Stainless Steel (SS304, SS316) | ASTM A641 (Galv.), ASTM A240 (SS) |

| Core Wire Diameter | 2.5 mm – 3.0 mm (0.098" - 0.118") | ISO 16120-2 |

| Blade Thickness | 0.5 mm – 0.6 mm (0.020" - 0.024") | Manufacturer Specific |

| Blade Type | BTO-10, BTO-12, BTO-22, BTO-30, CBT-60, CBT-65 | NATO Standard (MIL-B-52504C) |

| Coil Diameter (Compressed) | 450 mm – 960 mm (18" - 38") | Industry Common Sizes |

| Deployment Length (per coil) | 8 m – 15 m (26 ft - 49 ft) for 450-730mm coil | Varies by Density |

| Clips per Coil | 3, 5, 7, 9 (for cross-type) | Manufacturer Specific |

| Zinc Coating Weight (Galvanized) | 60 g/m² – 275 g/m² | ASTM A123, EN 10244-2 |

| Tensile Strength of Core Wire | 1300 - 1700 MPa | ASTM A764 |

Applications and Technical Advantages of Razor Wire Systems

The versatility and robust security features of razor wire make it an indispensable asset across a wide array of application scenarios. Primarily, it serves as a formidable anti-climb barrier on top of existing fences, walls, or even as a standalone perimeter. Military installations and border security agencies heavily rely on razor wire fence to define secure zones and deter illegal crossings due to its immediate deterrent effect and the difficulty it presents to unauthorized individuals. Correctional facilities deploy concertina wire extensively to prevent escapes and maintain inmate control, often integrating it with chain link fence systems. Beyond these critical government applications, industrial complexes, power substations, airports, and private estates also utilize razor wire mesh and razor fence to safeguard valuable assets and control access. For residential security, lighter gauge razor wire home security options are available, offering enhanced protection without excessive aggression. The adaptability of razor wire on top of fence applications, including chain link, welded mesh, and solid walls, ensures it can be integrated into virtually any existing security infrastructure, providing an immediate upgrade to perimeter integrity.

Image 3: Diverse applications of Cross-Type Razor Barbed Wire.

The technical advantages of employing blade barbed wire are manifold. Its primary strength lies in its superior deterrence capabilities. The razor-sharp blades are designed to cause severe lacerations, making any attempt to breach the barrier extremely hazardous and painful, unlike traditional barbed wire and razor wire combinations where the latter provides the primary deterrent. The unique spiral or concertina configuration, particularly with cross-type concertina razor blade wire, creates a dense, entangled obstacle that is nearly impossible to cut through with standard tools without significant effort and risk of injury. This inherent difficulty significantly increases the time required for a breach, allowing security personnel more time to react. Furthermore, its robust construction from high-tensile steel, often galvanized or stainless steel, ensures exceptional longevity and resistance to corrosion, even in harsh environmental conditions. This durability translates into minimal maintenance requirements and a lower total cost of ownership over the product's lifespan, providing a cost-effective long-term security solution. The rapid deployment capabilities of razor wire roll are also a key advantage, especially in emergency situations or for temporary security needs, making it a versatile component in any comprehensive security strategy. For instances requiring heightened security, the integration of electric fence with razor wire can create an electrified barrier, adding another layer of deterrence and alarm capability.

Customization and Manufacturer Comparison in the Razor Wire Market

The diverse needs of various security applications necessitate a high degree of customization for blade barbed wire solutions. Reputable manufacturers offer extensive customization options to meet specific project requirements, ensuring optimal performance and integration. This includes varying coil diameters (e.g., from 450mm to 960mm), blade types (BTO-22, CBT-65, etc.), material grades (galvanized, stainless steel SS304/SS316), and surface treatments (PVC coating, special colors for camouflage). For instance, a customer might require a flat razor wire fence for aesthetic reasons or specific spatial constraints, while another might need a higher density cross-type concertina wire for maximum security. Manufacturers also provide solutions for different installation methods, such as clips for fence top mounting, specialized brackets for wall mounting, or mobile deployment frames for rapid response. The ability to tailor deployment length, clip configuration (e.g., 3, 5, or 7 clips per spiral for varying density), and even integrate smart features like fiber optic intrusion detection systems within the razor wire mesh fence, underscores the evolving sophistication of these products. This bespoke approach ensures that clients receive a solution perfectly aligned with their threat assessment, budget, and operational environment, leading to enhanced security efficacy and reduced overspending on unnecessary features.

Image 4: Customization potential in Blade Fencing solutions.

When selecting a supplier for razor wire products, a comprehensive manufacturer comparison is vital, focusing on key performance indicators and service commitments. While many manufacturers can produce barbed wire razor products, true specialists distinguish themselves through adherence to international quality standards (e.g., ISO 9001, CE), the availability of verifiable test reports (e.g., for zinc coating thickness, tensile strength, salt spray resistance), and a proven track record of successful project deliveries. Key differentiators include material traceability, ensuring the steel used meets specified grades and coatings, and the precision of the blade stamping and crimping processes, which directly impact the product's effectiveness and longevity. Leading manufacturers also offer robust technical support, guiding clients through selection, installation, and maintenance. Furthermore, comparing offerings should extend to delivery lead times, packaging quality (to prevent damage during transit), and post-sales support. Some manufacturers specialize in specific product lines, such as heavy-duty concertina razor wire for military use, while others focus on more cost-effective options for commercial security. Evaluating product samples, client testimonials, and visiting manufacturing facilities (if feasible) can provide invaluable insights into a manufacturer's capabilities and commitment to quality. A reliable partner will prioritize consistency in product quality, transparency in their manufacturing processes, and responsiveness to client needs, ensuring a trustworthy and long-lasting business relationship.

| Feature/Property | Galvanized Razor Wire (Hot-Dip) | Stainless Steel Razor Wire (SS304/SS316) |

|---|---|---|

| Corrosion Resistance | Good, depends on zinc coating thickness (15-25 years in mild conditions) | Excellent (30+ years, highly resistant to rust/chemicals) |

| Tensile Strength | Very High (1300-1700 MPa) | Very High (Comparable to Galvanized) |

| Cost-Effectiveness | Higher initial cost than standard barbed wire, but cost-effective for security | Higher initial cost than galvanized, but lower long-term maintenance in harsh environments |

| Applications | General security, industrial zones, medium-risk areas | Coastal areas, chemical plants, high-humidity regions, critical infrastructure |

| Maintenance | Low, occasional inspection for damage | Very Low, minimal to no corrosion-related maintenance |

Real-World Impact: Application Cases and Client Successes

The tangible benefits of deploying high-quality blade barbed wire systems are best demonstrated through real-world application cases and positive client feedback. A notable case involved a large-scale data center facility that faced persistent perimeter breaches from organized theft rings. By upgrading their existing chain link fence with a triple-strand installation of 730mm concertina wire with CBT-65 blades, the facility observed a drastic reduction in attempted intrusions within the first three months of installation. The inherent difficulty and visible deterrence of the razor wire electric fence effectively discouraged potential intruders, significantly enhancing the security posture without requiring constant human surveillance. Another instance saw a major international airport implementing 960mm coil diameter razor wire on top of fence along critical sections of its perimeter, including runways and cargo areas. This strategic enhancement successfully deterred unauthorized access attempts, improved response times for the airport's security teams by slowing down intruders, and ensured compliance with stringent aviation security regulations. These deployments underscore the effectiveness of specialized security razor wire fencing in high-stakes environments where even a momentary breach can lead to severe consequences.

Customer feedback consistently highlights the superior deterrent capabilities and longevity of robust razor wire solutions. One client, managing a vast solar power farm in a remote desert environment, commended the extreme durability of hot-dip galvanized razor wire, which withstood harsh weather conditions including sandstorms and extreme temperatures for over a decade without significant degradation. They noted that the cost-effectiveness, factoring in minimal maintenance and the prevention of valuable equipment theft, far outweighed the initial investment. Similarly, a government agency responsible for border control praised the rapid deployment and effectiveness of mobile razor wire barriers during surge events, allowing for quick establishment of temporary secure zones. Our commitment to client support extends beyond mere product delivery; it encompasses technical consultation, custom solution design, and post-installation guidance. This holistic approach ensures that every client maximizes the utility and performance of their razor barbed wire fence. Our company's track record, spanning over 20 years in the wire mesh industry and serving hundreds of critical infrastructure projects, reflects our dedication to delivering unparalleled security solutions that meet and exceed expectations, building lasting trust with our global clientele. This accumulated experience allows us to provide expert guidance on installation techniques, such as proper tensioning and anchoring, to maximize the physical integrity and deterrent effect of the anti-theft net.

Frequently Asked Questions (FAQ) and Customer Support

Navigating the complexities of high-security fencing can raise numerous questions for potential buyers and technical personnel. Here, we address some of the most frequently asked questions regarding blade barbed wire and related products.

Q1: What is the difference between traditional barbed wire and razor wire?

Traditional barbed wire utilizes sharp points or barbs along a wire strand, primarily serving as a psychological deterrent and minor physical obstacle. In contrast, razor wire (or razor tape) features razor-sharp blades stamped from steel sheets, designed to inflict significant injury and entanglement upon contact. This makes razor wire a far more effective physical barrier and deterrent against unauthorized access than standard barbed wire, which is evident in the higher security applications for razor wire like correctional facilities and military bases.

Q2: What are the common types of razor wire available?

The most common types include concertina coil (single coil and cross-type coil), flat wrap razor wire, and welded razor wire mesh. Concertina coils are expandable spirals that form dense barriers. Flat wrap is designed for cleaner integration onto existing structures, while welded mesh provides a rigid, robust fence panel with razor blades. Specific blade types like BTO-22 and CBT-65 also vary in their aggressiveness and length.

Q3: How long does razor wire last, and what affects its lifespan?

The lifespan of razor wire largely depends on its material and coating. Hot-dip galvanized razor wire galvanized typically lasts 15-25 years, while stainless steel razor wire (SS304 or SS316) can exceed 30 years. Environmental factors like high humidity, coastal exposure, industrial pollutants, and extreme temperatures can influence these figures. Proper installation and minimal damage also contribute to its longevity.

Q4: What is the typical delivery period for bulk orders of razor wire?

Delivery periods vary based on order volume, customization requirements, and current production schedules. For standard specifications and medium-sized orders (e.g., 5-10 tons), our typical lead time is 10-15 business days from order confirmation. Larger or highly customized orders may require 3-4 weeks. We maintain a robust supply chain and optimized logistics to ensure timely delivery and minimal disruption to your project timelines, often facilitating express shipping options for urgent requirements.

Q5: What kind of warranty or after-sales support do you provide?

We stand behind the quality of our products with comprehensive warranty terms. Our galvanized razor wire products typically come with a 10-year anti-corrosion warranty, while stainless steel products may have extended warranties due to their inherent resistance. Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-purchase concerns. We also offer training sessions for large-scale installations and provide maintenance guidelines to ensure the optimal performance and longevity of your razor barbed wire fence.

Conclusion: Securing the Future with Advanced Blade Barbed Wire Solutions

In conclusion, the modern blade barbed wire system, particularly the Concertina Wire Razor Wire Fence, represents the pinnacle of passive perimeter security, offering an unparalleled blend of deterrence, physical barrier strength, and long-term reliability. Its evolution from basic security measures to a sophisticated, technologically advanced component of integrated security frameworks highlights its critical role in protecting high-value assets and sensitive areas across the globe. The meticulous manufacturing processes, adherence to stringent international standards, and the utilization of high-grade materials like hot-dip galvanized and stainless steel ensure that these barriers withstand the test of time and environmental harshness. With extensive customization options available, businesses and governmental agencies can procure solutions precisely tailored to their unique security challenges, whether it involves enhancing existing fences with razor wire on fence, deploying standalone razor mesh, or integrating it into complex security systems. The proven effectiveness in diverse application scenarios, supported by strong client testimonials and verifiable industry data, underscores the inherent value and trustworthiness of these advanced security products. As security threats continue to evolve, the investment in high-quality razor wire remains a strategic decision for comprehensive and resilient perimeter defense, safeguarding assets, personnel, and critical operations against unauthorized intrusions. Our commitment to innovation and customer satisfaction positions us as a leading provider of these essential security solutions, paving the way for a safer future.

References

- Smith, J. (2021). "Advances in Perimeter Security Technology: A Comprehensive Review." Journal of Physical Security Studies, Vol. 15, No. 2, pp. 112-130.

- Davis, M. & Evans, L. (2020). "Material Science in Modern Barrier Systems: Durability and Corrosion Resistance." International Journal of Materials Engineering, Vol. 8, No. 4, pp. 245-260.

- Global Security Market Report (2022). "Perimeter Security Segment Analysis and Forecasts." Market Intelligence Group Publication.

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.