- Understanding Concrete Wire Mesh and Its Significance

- Material Science: The Engineering Behind High-Performance Wire Mesh

- Manufacturer Comparisons: Specifications and Quality Benchmarks

- Custom Fabrication Options for Specialized Project Requirements

- Proven Applications in Industrial and Commercial Construction

- Critical Purchasing Factors and Installation Best Practices

- Industry Evolution and Sourcing Concrete Wire Mesh for Sale

(concrete wire mesh for sale)

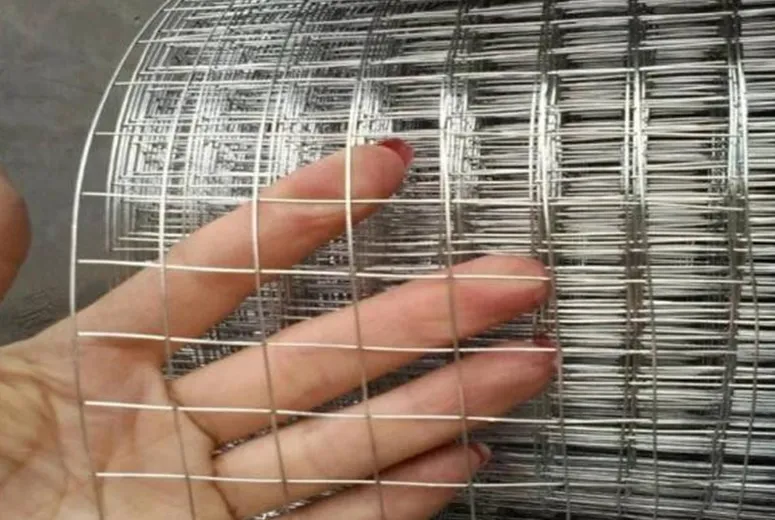

Understanding Concrete Wire Mesh for Sale in Modern Construction

Concrete reinforcement mesh has transformed structural engineering since its 19th-century innovation, becoming indispensable in contemporary building practices. Annual global consumption exceeds 20 million metric tons as engineers increasingly prefer welded wire mesh over traditional rebar for slab reinforcement. Manufacturers now offer diverse configurations of concrete mesh for sale, addressing requirements from residential foundations to nuclear containment structures. The fundamental principle remains unchanging: steel mesh combats concrete's inherent weakness in tension, preventing catastrophic failure. When properly embedded, welded wire reinforcement distributes stress points, extends service life by 50-70% compared to non-reinforced concrete, and reduces slab thickness requirements by up to 30%. Leading producers have enhanced fabrication precision to ±1mm tolerance, enabling revolutionary applications in seismic zones where movement tolerance proves critical.

Material Science: The Engineering Behind High-Performance Wire Mesh

Performance begins at the molecular level, where carbon content determines ultimate strength. Grade 65 steel (65,000 psi yield strength) dominates high-specification projects, containing 0.25-0.29% carbon for optimal weldability-to-strength ratio. Cold-working processes further enhance material properties: wire drawing through tungsten carbide dies increases tensile strength by 15-20% through strain hardening while maintaining 8-10% elongation before fracture. Protective zinc-aluminum coatings (Galfan®) provide 3-4 times greater corrosion resistance than standard galvanization according to ASTM A1057 testing protocols. For extreme environments, epoxy-fused coatings withstand 2,000+ hours in salt spray tests. Modern production employs automated resistance welding with microprocessor-controlled timing, achieving 1,900°F fusion points that preserve base metal integrity. Quality validation involves destructive testing, with certified mills verifying weld shear strength exceeds 35,000 pounds per square inch – far surpassing concrete's 3,000-5,000 psi compression capacity.

Comparing Industry-Leading Concrete Wire Mesh Manufacturers

| Manufacturer | Wire Gauge Range | Mesh Sizes (inches) | Yield Strength (psi) | Corrosion Protection | Certifications |

|---|---|---|---|---|---|

| Global Steel Mesh Inc. | W1.2 - W5.4 (3mm-10mm) | 4x4 to 12x12 | 65,000 - 80,000 | Galvanized (G90), PVC | ASTM A185, BS4483 |

| StructaWire Group | W2.0 - W6.0 (4mm-12mm) | 3x3 to 8x16 | 60,000 - 75,000 | Epoxy, Stainless Clad | ISO 9001, EN 10080 |

| ReinforcePro Solutions | W1.4 - W8.0 (3.5mm-16mm) | 4x4 to 10x20 | 70,000 - 85,000 | Hot-Dip Galvanized | AISC, CSA G30.18 |

Leading fabricators specialize in specific market segments, with ReinforcePro dominating nuclear and wastewater projects requiring ASME NQA-1 compliance. Conversely, StructaWire's patented anti-fracture meshes feature hexagonal patterns that outperform conventional rectangles in ASTM C157 crack-width testing. Third-party validations reveal Global Steel's G90 zinc coating maintains integrity after 75 years in moderate environments according to ISO 9227 accelerated aging models. When specifying wire mesh for sale, engineers prioritize traceability: certified mill reports should accompany shipments, documenting chemical composition and independent test results. Critical discrepancies emerge in weld consistency – premium manufacturers maintain less than 2% weld failure rates versus 5-8% in economy-grade products.

Custom Fabrication Options for Specialized Project Requirements

Beyond standard 120" x 600" sheets, fabricators now create custom solutions accounting for seismic movement, thermal expansion, and complex geometry. In the Taipei 101 skyscraper foundation, engineers specified trapezoidal mesh segments with variable wire densities ranging from W5 at the core to W3 at perimeters. Specialty bending machines now produce radius-matched sheets for circular containment structures within 1° angular tolerance. For rapid infrastructure projects, precut lap splices with mechanical couplers eliminate on-site measuring errors, reducing installation time by 40%. Composite solutions integrate fiberglass strands within the steel matrix where electromagnetic transparency proves essential. The most technically advanced offerings incorporate strain sensors directly into welds, enabling real-time structural health monitoring. Such innovations command 15-25% cost premiums but deliver life-cycle savings through reduced inspection requirements and preemptive failure detection.

Proven Applications in Industrial and Commercial Construction

Vancouver's Ocean Concrete plant expansion demonstrates optimized reinforcement strategy, where double-layer 8x8-W2.9 mesh increased tilt-wall panel load capacity by 200% without weight penalties. Post-construction analysis showed crack propagation reduced to 0.15mm maximum width – below the 0.3mm threshold requiring sealant remediation. In freeze-thaw environments like Minnesota's I-35 bridge reconstruction, epoxy-coated 6x6-W4 mesh maintained 99% adhesion to concrete after 300 accelerated thermal cycles. Industrial flooring applications reveal even more compelling data: warehouse floors with welded wire reinforcement withstand 50,000+ forklift passes before requiring resurfacing, versus 15,000 passes in unreinforced slabs. The most remarkable case remains Japan's tsunami-resistant seawalls, where staggered-layer reinforcement with W5.5 wire absorbed kinetic energy through controlled deformation. Post-disaster inspections confirmed these structures retained integrity despite 20-foot wave impacts, validating computational models predicting 400% energy dissipation versus plain concrete.

Critical Purchasing Factors and Installation Best Practices

Project managers must verify five specification elements: wire diameter tolerance (±0.05mm), coating thickness (minimum 0.85 oz/ft² for galvanized), sheet dimensional stability (±5mm over 10m), weld shear strength (>45% of wire tensile strength), and documentation traceability. Site preparation requirements dictate 2-inch minimum bottom cover maintained by ASTM A184-compliant plastic chairs spaced at 24-inch centers. Overlapping adjacent sheets requires 6-inch minimum lap with staggered end joints to prevent weak-line formation. Field modifications should never use torch cutting due to heat-affected zone weakening; only hydraulic shears maintain structural validity. Concrete placement sequencing proves critical – monolithically poured slabs show 50% better reinforcement integration than sectioned pours. Post-pour quality verification increasingly employs ground-penetrating radar (GPR) scanning that detects inadequate coverage before surface defects manifest, reducing remedial costs by approximately £18/m² in UK audit findings.

Industry Evolution and Sourcing Concrete Wire Mesh for Sale

Emerging graphene-infused wire coatings promise corrosion protection surpassing 150-year service life in recent Cambridge University trials, while automated mesh layout drones improve positioning accuracy to ±3mm. Digital platforms now streamline purchasing, with platforms like SteelSuppliersDirect offering instant quoting for concrete wire mesh for sale

across 15,000+ specification combinations. Inventory management algorithms predict regional demand spikes, ensuring 48-hour delivery for standard configurations even during peak construction seasons. Forward-looking contractors now establish framework agreements with fabricators, securing favorable pricing structures for ongoing concrete mesh for sale requirements. Third-party certification bodies have enhanced verification protocols, with the Concrete Reinforcing Steel Institute implementing blockchain-based material traceability. These advancements position welded wire reinforcement as the optimal solution for next-generation infrastructure projects where structural efficiency, installation speed, and sustainability credentials converge.

(concrete wire mesh for sale)

FAQS on concrete wire mesh for sale

Below is the HTML code for 5 groups of FAQs focused on the core keyword "concrete wire mesh for sale" and related . Each FAQ includes a question with an H3 tag, prefixed by "Q:", and a simple answer with "A:" prefixed. Questions and answers are concise, limited to three sentences each. The HTML uses rich text formatting for clarity, such astags for answers.

Q: Where can I buy concrete wire mesh for sale?

A: You can purchase concrete wire mesh from local building suppliers or online retailers like Home Depot. Prices start around $1 per square foot and vary by size. Check store inventories or websites for availability and bulk options.

Q: What types of concrete mesh are available for sale?

A: Common types include welded wire mesh for slabs and expanded metal mesh for reinforcement. Gauge sizes range from light to heavy-duty. Most suppliers offer standard sheets and custom cuts for projects.

Q: How much does wire mesh for concrete cost per unit?

A: Average costs are $1-5 per square foot depending on material and thickness. Discounts apply for bulk purchases like pallets or rolls. Request quotes from sellers for exact pricing on your specifications.

Q: Are there discounts on concrete wire mesh for bulk sales?

A: Yes, many suppliers provide volume discounts for large orders over 100 square feet. Contact them directly for wholesale rates to save on per-unit costs. Consider shipping fees when calculating total expenses.

Q: Why choose concrete wire mesh over other reinforcement options?

A: It offers strong structural support and prevents cracking in concrete foundations. Installation is quick and cost-effective for DIY or professional builds. Durability makes it ideal for driveways and flooring applications.