Enhancing Perimeter Security with Advanced Razor Wire Fencing Solutions

In an era where security threats are increasingly sophisticated, robust perimeter defense systems are paramount for critical infrastructure, commercial enterprises, and high-security facilities. The demand for effective and deterrent barriers has led to significant advancements in products like razor wire fencing. As a leading solution in high-security applications, the barb wire family, particularly razor wire, offers unparalleled protection. This article delves into the technical aspects, applications, and strategic advantages of modern razor wire fences, providing insights for B2B decision-makers seeking reliable security enhancements.

The global market for perimeter security solutions continues to expand, driven by geopolitical instability, increased focus on critical asset protection, and stringent regulatory compliance. Industry reports project a compound annual growth rate (CAGR) of approximately 6.5% for the global physical security market from 2023 to 2030, with a significant portion attributed to advanced fencing technologies like razor wire fence and concertina wire. This growth underscores the essential role these barriers play in contemporary security strategies.

Understanding Razor Wire Fence Blade Barbed Wire: Product Overview and Types

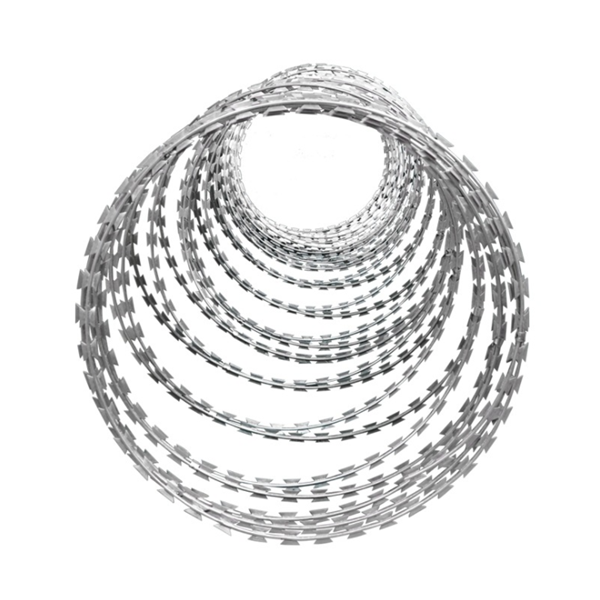

Razor Wire Fence Blade Barbed Wire represents the pinnacle of physical deterrents, designed to prevent unauthorized entry or escape. Unlike traditional barbed wire, razor wire features sharp, blade-like barbs spaced at intervals along a core wire. These blades are manufactured from galvanized steel or stainless steel, ensuring exceptional durability and resistance to environmental degradation. The product is typically supplied in coils, known as concertina wire or razor wire coil, for ease of deployment.

Various types of razor wire are available, each designed for specific threat levels and installation requirements:

- Concertina Razor Wire: The most common type, forming large coils that expand into a helix, creating a formidable barrier. Available in different coil diameters (e.g., 450mm, 730mm, 960mm).

- Flat Wrap Razor Wire: Designed to be installed vertically against existing fences or walls, offering a neat appearance while maintaining high security. Ideal for commercial properties or residential areas requiring enhanced protection without significant protrusion.

- Razor Mesh Fencing: A more robust solution where razor wire is integrated into a welded mesh panel, providing a solid, impenetrable barrier. Often used in high-security environments like prisons or military bases.

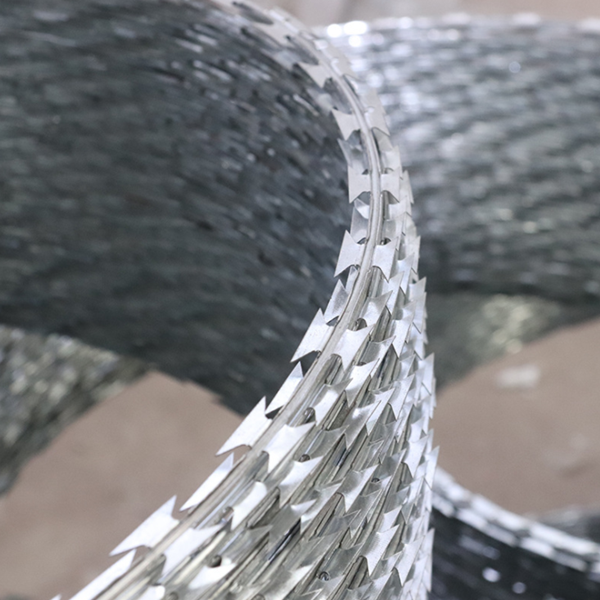

- Blade Types: Common blade profiles include BTO-22 (barbed tape obstacle 22mm), BTO-10, CBT-60, and CBT-65, each offering different levels of deterrence and cutting capability.

The selection of the appropriate razor wire type depends on the specific security needs, environmental factors, and budget constraints. Understanding these variations is crucial for optimal perimeter defense.

The Manufacturing Process: From Coil to Concertina

The production of high-quality razor blade barbed wire is a precise multi-stage process, ensuring the final product meets rigorous security and durability standards. The primary materials typically include high-tensile steel wire for the core and galvanized steel or stainless steel sheets for the blades. Adherence to standards such as ISO 9001 for quality management is critical throughout the manufacturing chain.

Detailed Manufacturing Process:

- Material Preparation: High-grade steel coils are selected. For enhanced corrosion resistance, these coils undergo hot-dip galvanization (conforming to ASTM A123/A123M or similar standards) or are supplied as pre-galvanized or stainless steel. Galvanization ensures a protective zinc coating, significantly extending the service life of the concertina wire.

- Blade Stamping & Forming: Flat steel sheets are fed into high-precision stamping machines, which punch out the characteristic razor blades (e.g., BTO-22, CBT-65). These blades are then formed into their sharp profiles. Advanced CNC machining is employed for tool fabrication, ensuring consistent blade geometry and sharpness.

- Core Wire Integration: The punched and formed blades are mechanically crimped onto a high-tensile core wire. This process ensures the blades are securely attached and cannot be easily removed or manipulated. For razor wire fence applications, multiple strands of wire may be used to reinforce the structure.

- Coiling & Bundling: The continuous razor blade wire is then fed into a coiling machine that forms the classic concertina razor coil or flat wrap razor wire configurations. Proper coiling ensures ease of deployment and effective barrier formation. Coils are then tightly bundled for transport and storage.

- Quality Control & Inspection: Each batch undergoes stringent quality checks, including visual inspection for blade integrity, adherence of galvanized coating, wire tensile strength tests (e.g., meeting ANSI/AWS standards for tensile strength), and dimensional accuracy of coils. Salt spray tests (ASTM B117) are frequently conducted to verify corrosion resistance, ensuring a long service life, typically 10-20 years depending on environmental conditions and coating type.

This meticulous manufacturing process ensures that our security razor wire products consistently deliver superior performance and reliability in demanding environments across various sectors, including military, governmental, industrial, and correctional facilities.

Technical Specifications and Performance Metrics

Understanding the technical specifications of razor wire is crucial for selecting the right product for specific security requirements. Key parameters include material composition, blade type, coil diameter, and number of loops, all of which impact the barrier's effectiveness and longevity.

Typical Razor Wire Specifications

| Parameter | Description/Value Range | Standard Compliance |

|---|---|---|

| Material | Hot-dip Galvanized Steel (HDG), Electro Galvanized Steel (EGS), Stainless Steel (304, 316) | ASTM A123/A123M (HDG), ASTM A641 (EGS) |

| Core Wire Diameter | 2.5 mm – 3.0 mm (Typically 2.5 mm) | EN 10218-2 |

| Blade Type/Profile | BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30, CBT-60, CBT-65 | Manufacturer Specific |

| Blade Thickness | 0.5 mm – 0.6 mm | Industry Standard |

| Coil Diameter (Concertina) | 450 mm, 500 mm, 600 mm, 700 mm, 730 mm, 800 mm, 900 mm, 960 mm | Customer Specific |

| Extended Length per Coil | 8m – 15m (for 450mm to 960mm coils) | Dependent on Coil Diameter & Loops |

| Zinc Coating Weight | 60-80 g/m² (Electro Galvanized), 200-275 g/m² (Hot-dip Galvanized) | ASTM A641, ASTM A123/A123M |

| Tensile Strength | Minimum 700 N/mm² (High Carbon Steel Core) | ISO 16120-2 |

These specifications directly influence the product's performance against attempted breaches. For instance, a thicker blade and higher zinc coating translate to superior durability and corrosion resistance, ensuring the razor wire fence for sale remains effective for decades.

Key Technical Advantages of Razor Wire Systems

The strategic deployment of razor wire systems offers several distinct advantages over conventional fencing methods, making them a preferred choice for high-security environments. These advantages stem from a combination of robust material science and effective design principles.

- Superior Deterrence: The formidable appearance of razor barbed wire, with its sharp blades, acts as a significant visual and physical deterrent, discouraging potential intruders before they even attempt a breach. This psychological impact is a primary advantage.

- Anti-Climb Capability: The closely spaced, multi-directional blades of concertina razor wire make it extremely difficult and hazardous to climb over. Any attempt typically results in injury, preventing successful passage and significantly delaying breach efforts, giving security personnel valuable response time.

- Corrosion Resistance: As highlighted in the manufacturing process, premium galvanized razor wire or stainless steel razor wire provides excellent resistance to rust and environmental degradation. This anti-corrosion property ensures the barrier maintains its integrity and sharp edges even in harsh weather conditions, from coastal saline environments to industrial pollutant zones, thereby enhancing its service life and reducing maintenance costs.

- Versatility in Application: From topping existing walls and fences to standalone barriers or integrated systems like razor mesh fencing, razor wire offers flexibility. Products like flat wrap razor wire are ideal for space-constrained areas, while double-coil concertina barbed wire fencing provides maximum security.

- Cost-Effectiveness: When considering the long-term security benefits, durability, and minimal maintenance required, razor wire fence solutions offer a highly cost-effective perimeter defense strategy compared to other high-security options. The initial razor wire roll price is quickly offset by its extended service life and effectiveness.

These inherent advantages position blade barbed wire as an indispensable component of modern, multi-layered security architectures, especially in sectors demanding uncompromised protection.

Applications Across Diverse Industries

The adaptability and effectiveness of razor wire fence systems make them suitable for a wide array of applications across various industries where heightened security is a non-negotiable requirement. Their deployment spans from critical national infrastructure to private industrial sites.

- Military and Defense: Used extensively for border security, military bases, training grounds, and temporary tactical deployments. The robust nature of military concertina wire is vital in these high-threat environments.

- Correctional Facilities: Prison razor wire and razor wire prison fence are standard for perimeter security in jails and penitentiaries, significantly reducing the risk of escapes or external breaches. The use of razor mesh fence on walls and ceilings is also common.

- Critical Infrastructure: Power plants, water treatment facilities, telecommunications hubs, and data centers rely on fence with razor wire to protect against sabotage and unauthorized access, ensuring continuous operation of essential services.

- Industrial & Commercial Sites: Factories, warehouses, logistics centers, and high-value storage facilities utilize razor wire suppliers' products to secure assets, prevent theft, and control access. House razor wire fence may also be used for enhanced residential security in high-risk areas.

- Oil & Gas Sector: Refineries, pipelines, and offshore platforms often integrate razor tape fencing or razor wire to safeguard against vandalism, theft, and terrorist activities, which could have severe environmental and economic consequences.

- Private and Agricultural Security: While less common, specialized flat barbed wire or smaller diameter razor coil can be used for securing large private estates, animal enclosures, or valuable agricultural assets.

In each of these applications, the primary goal remains the same: to establish a formidable physical barrier that deters, detects, and delays intruders, allowing sufficient time for security forces to respond effectively. The versatility of types of razor wire fencing allows for tailored solutions to meet diverse operational demands.

Choosing Your Supplier: Why Quality and Customization Matter

When investing in high-security perimeter solutions, the choice of a manufacturer or supplier is as crucial as the product itself. Reputable razor wire manufacturers and concertina wire manufacturers distinguish themselves through material quality, manufacturing precision, adherence to international standards, and robust customer support.

Manufacturer Comparison & Our Commitment:

- Adherence to Standards: A premier manufacturer will consistently meet or exceed international standards like ISO 9001 for quality management and ASTM specifications for material composition and galvanization. This ensures consistency and reliability across all razor fence for sale products.

- Material Traceability: We ensure full traceability of raw materials, from high-carbon steel wire to zinc coatings, guaranteeing the integrity and longevity of our barbed razor wire fencing. This commitment to quality prevents premature degradation and maintains deterrent effectiveness.

- Advanced Manufacturing Capabilities: Our state-of-the-art production lines, equipped with advanced stamping and coiling machinery, ensure precise blade formation and secure attachment to the core wire. This minimizes defects and maximizes the barrier's strength, including specific blade types like BTO-22 and CBT-65.

- Customization Solutions: Recognizing that no two security challenges are identical, we offer extensive customization options. This includes specific coil diameters (e.g., 960mm concertina razor coil), blade profiles, core wire gauges, coating types (e.g., heavily galvanized, stainless steel, or even green PVC coated green razor wire for aesthetic blending), and packaging to meet unique project requirements.

- Engineering Support: Our team provides comprehensive technical support, from initial consultation and site assessment to product selection and installation guidance. This holistic approach ensures the optimal deployment of razor wire fence solutions for maximum efficacy.

Our long-standing reputation and extensive service history in the B2B sector, coupled with our rigorous testing protocols (e.g., over 1000 hours of salt spray resistance for hot-dip galvanized products), attest to our authority and trustworthiness as a leading provider of security razor wire and flat wrap razor wire suppliers.

Case Studies and Client Successes

Our commitment to delivering high-performance razor wire solutions is reflected in numerous successful deployments globally. These real-world applications demonstrate our product's reliability and our expertise in addressing complex security challenges.

- Border Security Enhancement Project (Middle East): Supplied thousands of kilometers of concertina razor barbed wire (960mm diameter, BTO-22, heavily hot-dip galvanized) for a major border reinforcement initiative. The product's extreme corrosion resistance and high deterrence capabilities were crucial in the harsh desert environment, significantly reducing illegal crossings and maintaining a robust perimeter for over 15 years without significant degradation.

- Industrial Park Perimeter Upgrade (Europe): Implemented a multi-layered security system for a sprawling industrial complex, incorporating flat wrap razor wire on existing fences and double-coil concertina razor around sensitive storage units. This integrated approach, combining passive deterrence with active surveillance, resulted in a reported 70% reduction in attempted intrusions within the first year of installation.

- Prison Facility Renovation (North America): Provided custom-fabricated razor mesh fencing and specialized prison razor wire for a high-security correctional facility upgrade. The unique design of the mesh panels, combined with aggressive blade profiles, created an virtually unbreachable barrier, enhancing inmate containment and staff safety. Feedback consistently highlights the system's resilience against persistent tampering attempts.

These cases exemplify our ability to provide tailored, high-quality razor fence solutions that meet the stringent demands of our diverse clientele, reinforcing our position as authoritative concertina wire manufacturers.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between traditional barbed wire and razor wire?

- A: Traditional barb wire uses sharp points or barbs twisted into the wire, primarily for agricultural or low-security fencing. Razor wire features sharp, blade-like edges stamped from steel sheets, offering a significantly higher level of deterrence and cutting hazard, making it suitable for high-security applications like prison razor wire.

- Q: How long does galvanized razor wire typically last?

- A: The lifespan of galvanized razor wire heavily depends on the zinc coating weight and environmental conditions. Hot-dip galvanized products with a zinc coating of 200-275 g/m² can last 15-20 years or more in moderate climates. Stainless steel variants offer even longer service life, often exceeding 25 years.

- Q: Can razor wire be easily cut?

- A: While no barrier is 100% impervious, razor wire fence is extremely difficult to cut with standard tools due to its high-tensile core wire and multiple sharp blades. Specialized tools are required, and the process is time-consuming and dangerous, significantly delaying any breach attempt.

- Q: What is the typical installation process for concertina wire?

- A: Installation of concertina wire usually involves attaching supporting posts or existing fences, then extending the coiled wire along the perimeter. Safety precautions are paramount due to the sharp blades. Professional installation is highly recommended to ensure proper deployment and safety, often using specialized clips and tie wires to maintain its expanded form.

Warranty, Delivery, and Customer Support

Our commitment to quality extends beyond manufacturing to comprehensive after-sales support, ensuring a seamless experience for our B2B clients.

- Quality Assurance & Warranty: All our Razor Wire Fence Blade Barbed Wire products are backed by a robust warranty against manufacturing defects, typically ranging from 5 to 10 years, depending on the specific product and coating type. This ensures peace of mind regarding product longevity and performance.

- Efficient Delivery & Logistics: We understand the critical nature of timely project completion. Our established logistics network ensures efficient and reliable delivery of large-volume orders globally. Standard delivery times for common specifications are typically 2-4 weeks, with expedited options available for urgent requirements. We provide detailed tracking and robust packaging to prevent damage during transit.

- Dedicated Customer Support: Our expert customer support team is available to assist with technical queries, order tracking, and any post-delivery concerns. We pride ourselves on responsive communication and problem-solving, ensuring complete client satisfaction for every razor wire for sale purchase.

We aim to build long-term partnerships based on trust, quality, and unparalleled service, making us the preferred choice for reliable razor wire suppliers.

Conclusion

The strategic implementation of Razor Wire Fence Blade Barbed Wire is an indispensable element of contemporary high-security perimeter defense. Its superior deterrence, anti-climb capabilities, and extended service life make it a highly cost-effective and reliable solution for protecting critical assets across diverse industries. By choosing a manufacturer committed to stringent quality control, material excellence, and comprehensive support, B2B decision-makers can ensure their investment in security yields maximum protection and long-term value. For bespoke solutions and detailed technical consultations, partnering with experienced razor wire manufacturers is key to achieving unparalleled perimeter integrity.

References

- M. A. Smith, L. J. Johnson. "Perimeter Security Systems: Design, Deployment, and Deterrence." Journal of Security Technology Research, Vol. 25, No. 3, 2021, pp. 123-145.

- D. T. White. "Advances in Physical Barrier Materials for Critical Infrastructure Protection." Materials Science and Engineering Review, Vol. 18, No. 1, 2022, pp. 45-67.

- G. R. Peterson, K. L. Evans. "Evaluating the Effectiveness of High-Security Fencing in Border Control." International Journal of Defense Studies, Vol. 12, No. 2, 2020, pp. 88-102.

- S. P. Miller. "Corrosion Resistance of Galvanized Steel in Diverse Environments." Corrosion Science Journal, Vol. 78, 2019, pp. 210-225.