Product Overview

Black Twisted Annealed Wire is a specialized type of steel wire engineered for exceptional strength and flexibility. Manufactured from low-carbon steel, this wire undergoes a unique annealing process to enhance its malleability while maintaining structural integrity. The twisting of multiple wires together creates a twisted wire structure that significantly improves durability compared to standard wire types.

This product is widely used in construction, landscaping, and industrial binding applications. Its black color not only provides a sleek aesthetic but also offers enhanced resistance to environmental factors. The black annealed twisted wire is available in various configurations, including coil wire, spool wire, and bulk packaging, making it adaptable to diverse operational needs.

Key Features and Advantages

- Durability: The twisting process increases tensile strength, making it ideal for heavy-duty applications.

- Flexibility: Annealing ensures the wire remains easy to manipulate without compromising structural integrity.

- Corrosion Resistance: The black coating provides protection against oxidation and environmental degradation.

- Cost-Effective: Competitive pricing combined with long-term durability reduces replacement costs.

- Customization: Available in multiple configurations to suit specific project requirements.

The annealed tie wire is particularly favored in construction for its ability to withstand harsh conditions. Its rugged design makes it suitable for applications such as reinforcing concrete structures, securing scaffolding, and bundling materials in industrial settings.

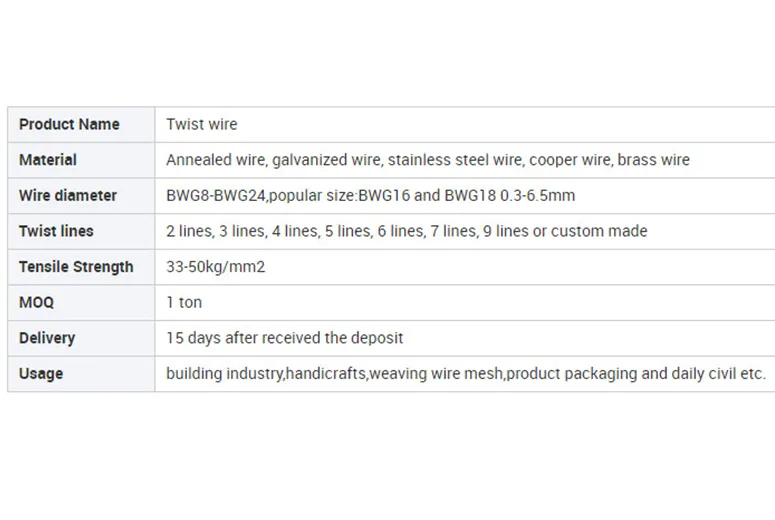

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Low Carbon Steel |

| Coating | Black Annealed and then twisted Finish |

| Tensile Strength | Varies by Diameter (Typically 350-550 MPa) |

| Diameter Range | 0.8mm - 4.0mm (Custom Options Available) |

| Twisting Configuration | 2-Wire to 6-Wire Twist |

| Packaging | Coil, Spool, or Bulk (Customizable) |

These specifications ensure the product meets international quality standards. For detailed technical data, refer to the product page or contact the manufacturer directly.

Applications in Construction and Industry

The black tie wire is a critical component in various industries:

- Construction: Used for binding rebar, securing formwork, and reinforcing concrete structures.

- Landscaping: Ideal for creating durable garden structures, fencing, and decorative elements.

- Industrial Packaging: Provides reliable bundling for materials like pipes, cables, and machinery parts.

- Manufacturing: Employed in the production of wire mesh and other metal products.

Its versatility is further enhanced by the ability to customize the wire's dimensions and configurations. For example, the twisted wire can be tailored to specific load-bearing requirements, making it suitable for both small-scale and large-scale projects.

Company Background and Expertise

Dingzhou Lanye Metal Products Co., Ltd. has been a trusted manufacturer of steel wire and wire mesh for over 15 years. The company's commitment to quality is reflected in its state-of-the-art production facilities and rigorous testing protocols. With a dedicated team of engineers and technicians, Lanye Metal ensures that every product meets global standards.

As highlighted in their FAQ section, the company emphasizes transparency and customer satisfaction. They offer free samples, detailed consultations, and flexible payment terms to cater to international clients. Their production process includes advanced double annealing lines, as demonstrated in this video.

Industry Standards and Quality Assurance

While the context does not explicitly mention NIST (National Institute of Standards and Technology) compliance, the principles of precision and reliability emphasized by NIST are closely aligned with the manufacturing standards of Dingzhou Lanye Metal Products Co., Ltd.. NIST's role in developing measurement standards for materials and manufacturing processes underscores the importance of rigorous quality control, a practice that Lanye Metal adheres to in its production of black annealed wire.

For further information on industry standards, refer to NIST's official resources: https://www.nist.gov.

Frequently Asked Questions (FAQ)

- Q1: Are you a manufacturer?

A: Yes, we are steel wire and wire mesh manufacturer for over 15 years. We have professional technicians and testing teams. - Q2: Do you have advantages in steel wire or wire mesh quality and price?

A: Our wire and wire mesh has world-class quality and it is internationally accredited, our wire price is in the middle level in China. - Q3: What is the average lead time?

A: For samples, the lead time is about 7 days. For mass production, the lead time is 20-40 days after receiving the deposit payment. - Q4: Do you have a minimum order quantity?

A: Yes, we require all international orders to have an ongoing minimum order quantity. The MOQ is different for each product, please contact us for further communication. - Q5: What's your payment terms?

A: We prefer T/T 30% as down payment, balance against B/L copy; We accept 100% LC at sight. - Q6: What are the characteristics of doing business with you?

A: We never cheat customers!

Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits.

Conclusion

The Black Twisted Annealed Wire from Dingzhou Lanye Metal Products Co., Ltd. exemplifies the perfect balance of strength, flexibility, and cost-effectiveness. Its wide range of applications and adherence to international quality standards make it a preferred choice for industries worldwide.

For more information about the product or to request samples, visit the official product page or contact the company directly. With a commitment to innovation and customer satisfaction, Lanye Metal continues to set benchmarks in the steel wire industry.