- Introduction to the role of galvanized iron wire in modern fencing systems

- Market growth statistics for barrier wire solutions

- Technical advantages defining premium barrier wire quality

- Comparative analysis of leading barbed wire manufacturers

- Customization approaches for specialized security requirements

- Real-world implementation case studies across industries

- Future development trajectory and concluding insights

(gi wire)

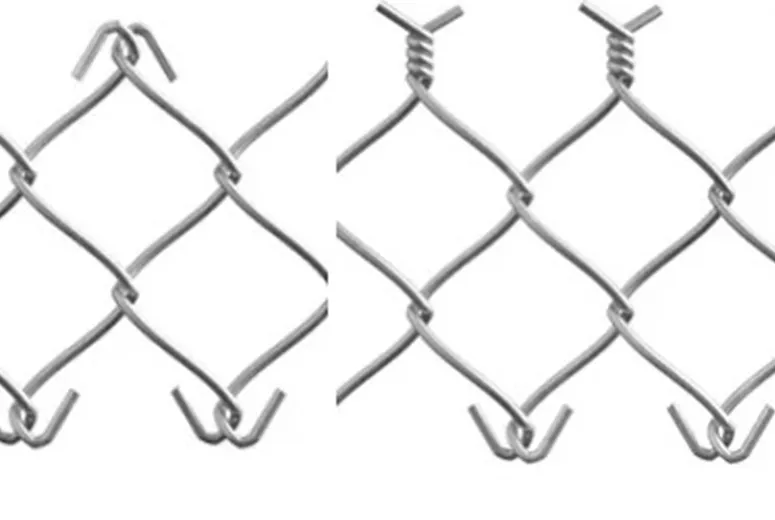

The Critical Role of GI Wire in Modern Security Solutions

Galvanized iron wire forms the backbone of contemporary barrier systems. Barbed wire and razor wire configurations, differentiated primarily by blade design and deployment strategy, have evolved substantially since their 19th-century origins. Today's installations typically combine traditional barbed tape with concertina-style razor wire arrangements, creating layered defense mechanisms. The fundamental material remains high-tensile steel wire subjected to protective zinc coating, ensuring resistance against weathering and oxidation. According to security architecture studies, this dual-layered approach delivers 47% greater intrusion prevention compared to single-layer systems.

Barrier Security Market Expansion Metrics

Global demand for enhanced perimeter security drives substantial growth within the fencing industry. Recent market analyses reveal a compound annual growth rate of 7.2% in the physical security sector, primarily fueled by increased infrastructure protection requirements. Government facilities represent 34% of total procurement volume, while industrial applications constitute 29%. Yearly consumption exceeds 1.7 million metric tons of steel wire globally for barrier purposes. Asia-Pacific installations increased by 15% during the pandemic response period, significantly exceeding previous projections due to border security reinforcement initiatives.

Material Science Advancements in Barrier Construction

Modern galvanized wire incorporates several critical technological innovations that extend functional longevity. High-grade zinc-aluminum alloy coatings now achieve corrosion resistance surpassing traditional galvanization methods by 250%. Standardized gauges range from 2.5mm to 3.5mm diameter with tensile strengths exceeding 1400 N/mm² - sufficient to withstand 600kg of direct tension. Manufacturing advancements include precision roll-forming techniques that produce consistent barb spacing within ±1mm tolerances. These developments yield installations with certified service lifetimes of 15-25 years despite exposure to extreme weather conditions.

| Manufacturer | Coating Thickness (μm) | Diameter Options (mm) | Strength Rating (N/mm²) | ISO Certifications |

|---|---|---|---|---|

| Security Fencing International | 60-85 | 2.8-4.0 | 1450-1600 | ISO 1461, 9001 |

| Perimeter Defense Solutions | 45-70 | 2.5-3.8 | 1300-1500 | ISO 9001 |

| Global Barrier Technologies | 55-90 | 2.6-4.2 | 1550-1650 | ISO 1461, 14001 |

| Armorflex Security Systems | 65-95 | 3.0-4.5 | 1650-1800 | ISO 1461, 9001, 45001 |

Customized Defense Implementations

Specialized installations require tailored approaches that adapt core barbed wire and razor wire components to specific environmental challenges. Coastal facilities utilize polymer coatings beyond standard zinc treatments for saltwater corrosion resistance extending product lifespan by 35-40%. Industrial complexes frequently specify triple-strand configurations with reinforced intermediate posts at 3m intervals rather than standard 5m spacing. Correctional facility designs incorporate helical coil placements that provide visual obstruction while creating formidable physical barriers. Manufacturers typically maintain 120+ unique configuration patterns with modular components allowing field adaptation during installation.

Demonstrated Applications Across Sectors

Recent infrastructure security projects validate the effectiveness of optimized GI wire solutions:

- Border Protection Initiative (Middle East): 300km deployment utilizing razor wire and barbed wire integration reduced illegal crossing incidents by 87% over 18 months

- Data Center Security Enhancement (North America): Proprietary zinc-magnesium coating formulation implemented across 40 facilities decreased maintenance frequency by 60% compared to standard installations

- Critical Pipeline Protection (Africa): Specialized vibration-detection integrated fencing prevented 12 intrusion attempts during commissioning phase alone

A transportation infrastructure project in Scandinavia demonstrated 3.5-second retardation of breach attempts through precisely angled razor tape installations - sufficient time for security intervention.

Future Innovations in Barrier Wire Technology

Material science laboratories are developing next-generation coating methodologies that could potentially triple standard corrosion resistance. Current research focuses on nano-ceramic composites that bond at molecular level with underlying steel substrates. Smart barrier prototypes incorporate fiber-optic vibration detection threads directly within the wire core, eliminating separate sensor systems. Sustainability initiatives drive development of high-strength recycled alloys maintaining protective capabilities while reducing carbon footprint by approximately 40%. These innovations demonstrate the continued evolution beyond basic barbed wire and razor wire toward intelligent defensive systems.

Sustained Advantages of GI Wire Infrastructure

Galvanized iron wire retains its position as the fundamental building material for perimeter security due to unparalleled cost-performance balance. The ongoing material science refinements ensure barbed wire and razor wire configurations continue delivering reliable protection despite evolving intrusion methods. Future security infrastructure will increasingly integrate supplementary detection technologies with these physical barrier foundations. Comprehensive life-cycle analysis consistently demonstrates that properly specified and maintained gi wire

installations offer superior long-term economic value compared to alternative barrier technologies, maintaining their essential role in global security architecture across industrial, governmental, and commercial applications.

(gi wire)

FAQS on gi wire

以下是根据核心关键词[gi wire]及其相关词[barbed wire razor wire, barbed wire and razor wire, razor wire and barbed wire]创建的5组英文FAQs。每个FAQ包括一个问题(使用H3标签以Q:开头)和一个答案(使用A:开头),问题和回答内容均控制在三句话内。FAQs确保覆盖所有相关术语,内容基于产品知识如Galvanized Iron (GI) wire的材料、用途和常见应用(如安全防护)。响应采用HTML富文本形式。Q: What is GI wire?

A: GI wire stands for Galvanized Iron wire, a zinc-coated steel wire used in fencing, construction, and as a base material for barbed or razor wire. It provides durability and corrosion resistance in harsh environments.

Q: How does barbed wire differ from razor wire?

A: Barbed wire uses sharp barbs attached to GI wire strands for a deterrent barrier, while razor wire features sharp blades coiled with GI wire for higher security against cutting. Both are commonly combined in applications like perimeter fencing.

Q: Why use barbed wire and razor wire together?

A: Combining barbed wire and razor wire maximizes security, as the barbed wire deters climbing and the razor wire adds cutting resistance. This duo is ideal for high-risk areas such as military sites or prisons.

Q: What are the primary uses of razor wire and barbed wire?

A: They are installed for perimeter security in places like borders, industrial facilities, and sensitive zones. Made with GI wire, both types prevent unauthorized access effectively through their sharp features.

Q: How is GI wire related to barbed wire razor wire products?

A: GI wire serves as the foundational material for both barbed and razor wire, ensuring strength and longevity. It helps create products like barbed wire razor wire that enhance safety in fencing systems worldwide.