Introduction

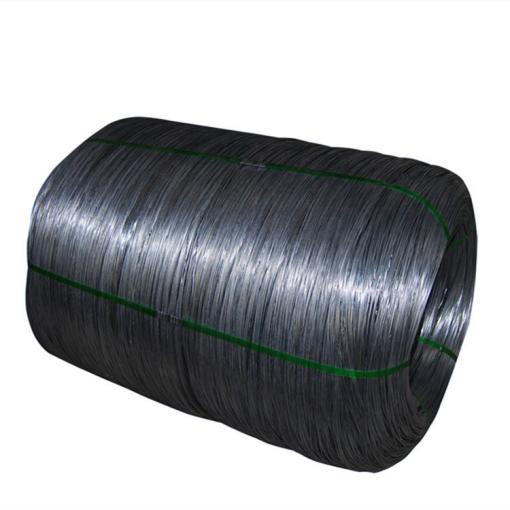

The High Quality Black Annealed Iron Wire Tie Wire is a specialized product designed to meet the demanding requirements of construction, industrial, and binding applications. Manufactured by Dingzhou Lanye Metal Products Co., Ltd., this wire is engineered to deliver exceptional flexibility, durability, and ease of use. This article provides an in-depth analysis of its features, technical specifications, applications, and the company's commitment to quality.

Product Features and Benefits

The Black Annealed Iron Wire Tie Wire is produced using a precise annealing process that enhances its mechanical properties. The wire is made from Q195-type drawing rod, which is heated to 1000°C and then cooled at an optimal rate. This process reduces hardness, improves machinability, and eliminates residual stress, ensuring stable dimensions and minimizing deformation risks. The result is a wire that is both flexible and strong, making it ideal for a wide range of applications.

Key advantages of this product include:

- Enhanced Flexibility: The annealing process refines the grain structure, allowing the wire to bend without breaking.

- Improved Durability: The reduction of internal stresses ensures the wire maintains its integrity under repeated use.

- Consistent Quality: The controlled manufacturing process guarantees uniformity in size and strength.

- Cost-Effective: The wire’s longevity reduces the need for frequent replacements, offering long-term value.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Iron wire or low carbon steel wire (Q195-type drawing rod) |

| Annealing Process | Heated to 1000°C, cooled at an optimal rate to reduce hardness and residual stress |

| Flexibility | Excellent due to grain refinement and structural reorganization |

| Dimensions | Available in coil, spool, or big package formats |

| Packaging | 25kg, 50kg, 500kg, 800kg, etc. |

| Surface Finish | Black annealed finish for enhanced corrosion resistance |

Applications and Use Cases

The Black Annealed Iron Wire Tie Wire is widely used in both industrial and construction settings. Its versatility makes it suitable for:

- Construction Materials: As a binding wire for securing steel rebars, concrete structures, and other building components.

- Industrial Binding: Used as baling wire for packaging materials, textiles, and agricultural products.

- Landscaping and Parks: Ideal for tying plants, trees, and garden structures due to its flexibility and strength.

- Manufacturing: Applied in the production of wire mesh, fencing, and other metal-based products.

Company Background: Dingzhou Lanye Metal Products Co., Ltd.

Based in China, Dingzhou Lanye Metal Products Co., Ltd. is a leading manufacturer of high-quality metal products, specializing in black annealed wire and related materials. The company is committed to the principles of "Super Good Quality, Satisfactory Service," ensuring that every product meets international standards.

Dingzhou Lanye has consistently invested in technological upgrades and production improvements to cater to the needs of global customers. Their focus on innovation and quality control has established them as a reliable partner for industries requiring durable and efficient metal solutions.

Quality Assurance and Industry Standards

The Black Annealed Iron Wire Tie Wire adheres to rigorous quality control measures, ensuring compliance with industry standards. According to the National Institute of Standards and Technology (NIST), materials used in construction and industrial applications must meet specific mechanical and chemical requirements to ensure safety and performance. While the product’s exact specifications may not be listed in NIST databases, the annealing process and material selection align with general standards for metallic materials used in structural and binding applications.

For further information on material testing standards, refer to the NIST website.

Conclusion

The High Quality Black Annealed Iron Wire Tie Wire from Dingzhou Lanye Metal Products Co., Ltd. is a premium solution for industries requiring durable, flexible, and cost-effective binding materials. Its advanced manufacturing process, combined with a commitment to quality, ensures it meets the demands of modern construction and industrial applications. Whether used for binding wire or industrial baling, this product stands out for its reliability and performance.