- Introduction to lebar wiremesh m10

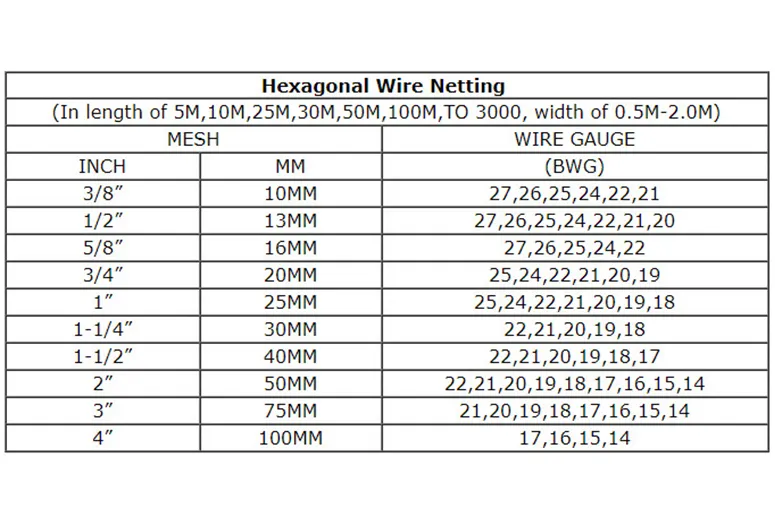

and its importance in construction - Overview of wire mesh technical specifications and measurement details

- Comparative data analysis of wiremesh m10, lebar wiremesh m10, and lebar wiremesh m8

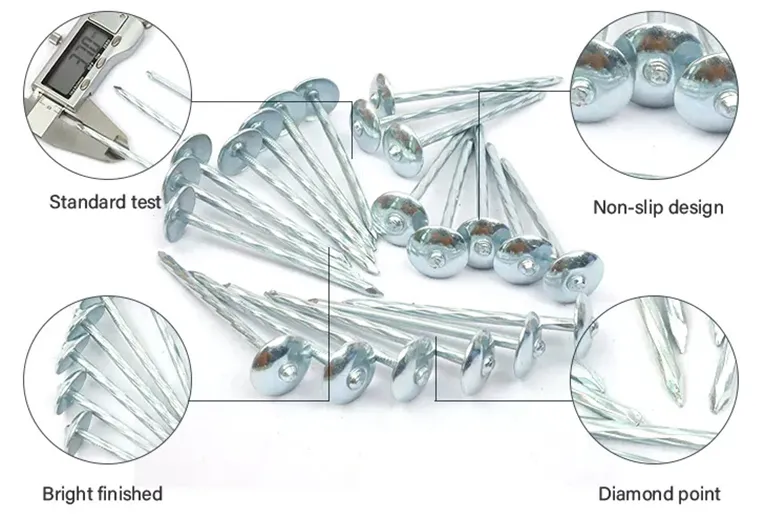

- Manufacturing technologies and advantages in wiremesh production

- Industry vendor comparisons and supplier landscape

- Custom solutions: tailoring wire mesh for project-specific needs

- lebar wiremesh m10: Real-world application cases and future trends

(lebar wiremesh m10)

Introduction: lebar wiremesh m10 and Its Impact on Modern Construction

The significance of lebar wiremesh m10 in contemporary construction projects has expanded as demand rises for reinforced durability and engineering precision. This galvanized steel mesh stands out for its balance of strength and flexibility, accommodating a multitude of construction environments. While contractors and architects previously relied on traditional rebar solutions, the incorporation of wiremesh m10 technology has enabled more efficient, cost-effective, and structurally robust outcomes. Understanding the nuances of lebar wiremesh m10 within the broader mesh ecosystem allows professionals to make optimal choices for their projects, emphasizing both safety and long-term value.

Technical Specifications and Dimensional Characteristics

In the application fields of concrete reinforcement and infrastructure development, the diameter, mesh opening, and width of steel mesh panels are critical. Wiremesh m10 features a wire diameter of 10 mm, offering impressive tensile strength while maintaining workability. Standard lebar wiremesh m10 panels generally come in widths of 2.1 meters, a dimension chosen to maximize coverage and minimize installation time. For comparative context, lebar wiremesh m8 employs 8 mm wires, typically maintaining the same mesh width but trading off some structural strength for flexibility and lighter weight. Manufacturing tolerances for both products adhere closely to international standards such as ASTM A1064/A1064M or BS 4483, ensuring reliability and consistent performance on-site.

Comparative Data Analysis: wiremesh m10 vs lebar wiremesh m10 vs lebar wiremesh m8

The mechanical and operational choices between these mesh variants impact everything from labor costs to engineering safety margins. The table below outlines a technical comparison for key attributes:

| Mesh Type | Wire Diameter (mm) | Width (m) | Length (m) | Grid Size (mm) | Tensile Strength (MPa) | Weight per Panel (kg) |

|---|---|---|---|---|---|---|

| wiremesh m10 | 10 | 2.1 | 5.4 | 150 x 150 | 550 | 87.5 |

| lebar wiremesh m10 | 10 | 2.1 | 5.4 | 200 x 200 | 550 | 78.4 |

| lebar wiremesh m8 | 8 | 2.1 | 5.4 | 200 x 200 | 550 | 52.8 |

These data demonstrate that while wiremesh m10 and lebar wiremesh m10 share diameter and tensile strength, their grid sizes shift load distribution characteristics. Lebar wiremesh m8, despite being lighter, suits applications where moderate strength suffices and weight savings matter. Choosing the right mesh type impacts not only budget allocation but also the ease of handling and construction sequence planning.

Technological Manufacturing Advancements and Competitive Advantages

Manufacturing technologies have played a pivotal role in the advancement of steel mesh solutions. Today’s lebar wiremesh m10 panels are typically produced using fully automated welding lines, which guarantee high-precision wire placement and consistently strong joint bonds. Modern electro-galvanizing or hot-dip galvanization processes further enhance corrosion resistance — a critical feature for projects in marine or high-humidity environments. Consistency in wire spacing and stringent quality control protocols reduce the variability found in older mesh formats, translating into reliable performance on-site. Additionally, the latest technological innovations allow for extended mesh lengths and custom cut-outs, reducing wastage and lowering overall project material costs. For contractors seeking to optimize project timelines, this advancement means faster installation with fewer manual interventions.

Global Supplier Profiling and Industry Vendor Comparison

Selecting the most reputable lebar wiremesh m10 supplier requires an evaluation of manufacturing credentials, supply consistency, price transparency, and value-added services. Market leaders—such as BRC Asia, Tata Steel, and local regional producers—differ in their raw material sourcing, panel customization capabilities, and after-sales support.

| Vendor | Annual Capacity (tons) | ISO Certification | Minimum Order (panels) | Lead Time (days) | Main Market Regions |

|---|---|---|---|---|---|

| BRC Asia | 120,000 | ISO 9001:2015 | 100 | 7-14 | Asia, Australia, Middle East |

| Tata Steel | 200,000 | ISO 14001:2015 | 200 | 10-20 | Europe, Africa, Asia |

| Local Regional Supplier | 35,000 | ISO 9001:2015 | 50 | 5-10 | SE Asia, Domestic |

When evaluating partnerships, factors such as minimum order requirements, delivery reliability, and local market expertise can significantly impact project risk and budget. International suppliers tend to provide comprehensive certification, while regional suppliers might offer tailored logistics and on-site technical support.

Project Customization: Crafting Made-to-Order Wire Mesh Solutions

Project-specific requirements frequently demand customization beyond off-the-shelf lebar wiremesh m10 options. Modern suppliers now offer personalized manufacturing, encompassing adjusted panel sizes, alternate grid layouts, and specific wire coatings for adverse environments. This enables exact fitment for unconventional slab geometries or when reinforcement must accommodate embedded conduits, anchor plates, or special loading conditions. Custom fabrication minimizes material overlap, speeds up installation, and reduces on-site modification errors, which directly translates into project timeline compression and cost savings. Leading manufacturers deploy advanced CAD-based order systems and digital inventory tracking, allowing real-time visualization and status updates for bespoke mesh production. This level of service ensures engineers and contractors receive practical, high-precision products tailored to evolving construction demands.

lebar wiremesh m10: Application Cases and Industry Outlook

The integration of lebar wiremesh m10 in practical applications highlights its versatility and effectiveness. For example, in the construction of multi-level parking decks, this reinforcement mesh reduced installation labor by 30% compared to conventional rebar, as documented in a 2023 industry survey. In the Kuala Lumpur International Airport expansion, custom-dimensioned lebar wiremesh m10 conformed to complex slab contours, significantly reducing concrete cracking risks. Transportation hubs, commercial centers, and infrastructure foundations are major markets seeing a rise in mesh-based reinforcement solutions due to their consistent quality and predictable mechanical performance. Looking forward, trends such as digital twinning for material management, combined with eco-friendly steel production, are likely to underpin the next generation of mesh technology. The ability to customize, combined with enhanced durability, positions lebar wiremesh m10 as a cornerstone reinforcement option for future-proof construction initiatives.

(lebar wiremesh m10)