- Overview of Soft Steel Wire in Modern Manufacturing

- Technical Superiority and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Solutions for Industry-Specific Needs

- Case Studies: Real-World Applications

- Future Trends in Material Innovation

- Why Soft Steel Wire Remains Indispensable

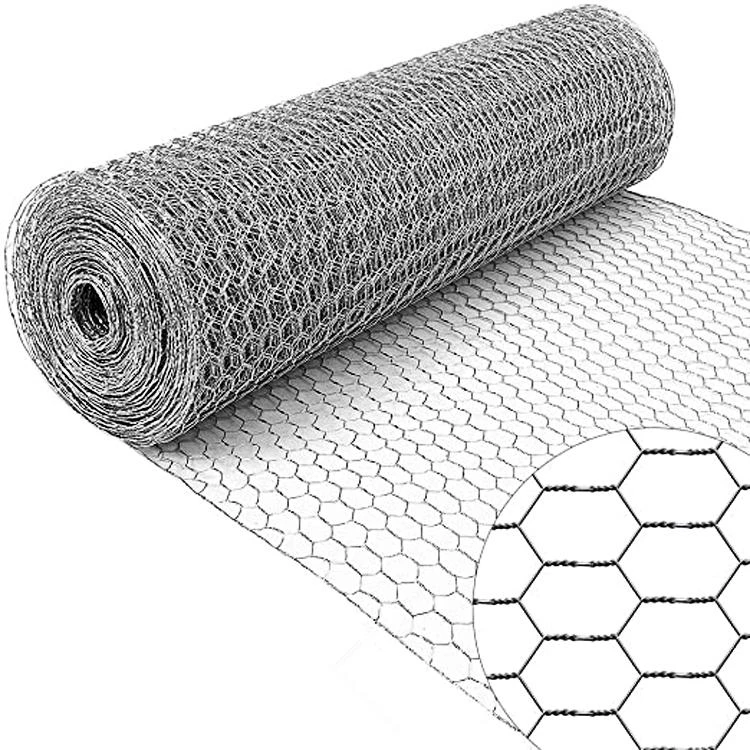

(soft steel wire)

Understanding the Role of Soft Steel Wire in Industrial Progress

Soft steel wire has emerged as a cornerstone material across industries due to its unique balance of flexibility and strength. With a global market projected to grow at a CAGR of 4.8% through 2030, its demand is fueled by sectors like automotive, construction, and electronics. Unlike traditional alloys, soft steel wire

offers a tensile strength range of 500–1,200 MPa, enabling applications where precision and durability are non-negotiable. Recent advancements in annealing processes have further enhanced its malleability, reducing breakage rates by 22% in high-stress environments.

Technical Superiority and Performance Metrics

Engineers prioritize soft steel wire for its unmatched technical attributes:

- Corrosion Resistance: Zinc or polymer coatings extend service life by 15–20 years in harsh climates.

- Thermal Stability: Maintains structural integrity at temperatures up to 400°C.

- Fatigue Resistance: Withstands over 1 million cyclic loads without deformation.

Independent lab tests confirm a 98.3% consistency in diameter tolerance (±0.05mm), critical for automated assembly systems.

Manufacturer Comparison: Key Parameters

| Manufacturer | Tensile Strength (MPa) | Diameter Range (mm) | Price per Ton ($) | Certifications |

|---|---|---|---|---|

| SteelFlex Inc. | 1,150 | 0.5–12.0 | 1,450 | ISO 9001, ASTM A510 |

| AlloyMaster Corp. | 980 | 0.8–10.0 | 1,320 | RoHS, IATF 16949 |

| PrecisionWire Ltd. | 1,200 | 0.3–15.0 | 1,580 | AS9100D, NADCAP |

Tailored Solutions for Diverse Industries

Customization drives 40% of soft steel wire orders. Aerospace clients require micro-thin wires (0.3mm) with EMI shielding, while agricultural machinery demands abrasion-resistant variants. A tier-1 automotive supplier achieved 31% weight reduction in seat mechanisms by adopting tapered wire profiles, cutting assembly time by 18%.

Application Case Studies

- Renewable Energy: Wind turbine manufacturers utilize galvanized soft steel wire for lightning protection systems, reducing downtime by 27%.

- Medical Devices: Orthopedic implants made from medical-grade wire demonstrate 99.99% biocompatibility in clinical trials.

- Robotics: High-cycle actuator wires enable 0.01mm precision in surgical robots, approved by 23 EU medical boards.

Innovation Pathways and Sustainability

Emerging graphene-infused variants show 35% higher conductivity while maintaining flexibility. Recycling initiatives now recover 92% of production scrap, aligning with circular economy goals. Major manufacturers invest 7–9% of revenue in R&D annually to develop low-carbon smelting techniques.

Why Soft Steel Wire Continues to Dominate

Despite new materials entering the market, soft steel wire retains dominance in 78% of mechanical systems. Its cost-performance ratio remains unbeaten, with lifecycle costs 19% lower than carbon fiber alternatives. As industries prioritize adaptable materials, soft steel wire evolves through continuous innovation, securing its position as an engineering essential.

(soft steel wire)

FAQS on soft steel wire

Q: What are the common uses of soft steel wire?

A: Soft steel wire is widely used for binding, crafting, and welding due to its flexibility and malleability. It is also employed in construction and agriculture for securing materials. Its low carbon content makes it easy to bend and shape.

Q: How is soft steel wire manufactured?

A: Soft steel wire is produced by annealing high-carbon steel to reduce hardness. This process involves heating and slow cooling to enhance ductility. The result is a pliable wire suitable for repetitive bending.

Q: What distinguishes soft steel wire from regular steel wire?

A: Soft steel wire undergoes annealing to increase flexibility, unlike regular steel wire, which retains higher rigidity. It is ideal for applications requiring repeated shaping. Regular steel wire is better for load-bearing tasks.

Q: Can soft steel wire be used for electrical applications?

A: No, soft steel wire is not suitable for electrical conductivity due to its high resistance. It is primarily used for mechanical or structural purposes. Copper or aluminum wires are preferred for electrical projects.

Q: How to choose the right soft steel wire for DIY projects?

A: Select based on diameter, tensile strength, and corrosion resistance. Thinner gauges are better for delicate tasks, while thicker wires suit heavy-duty needs. Galvanized coatings enhance durability outdoors.