- Introduction to standard welded wire mesh for concrete reinforcement

- The role of welded reinforcement mesh for concrete applications

- Technical advantages and key specifications

- Comparison of leading manufacturers—detailed data analysis

- Customization options for diverse construction requirements

- Real-world application cases and performance outcomes

- Conclusion: Maximizing value with standard welded wire mesh for concrete reinforcement

(standard welded wire mesh for concrete reinforcement)

Introduction to Standard Welded Wire Mesh for Concrete Reinforcement

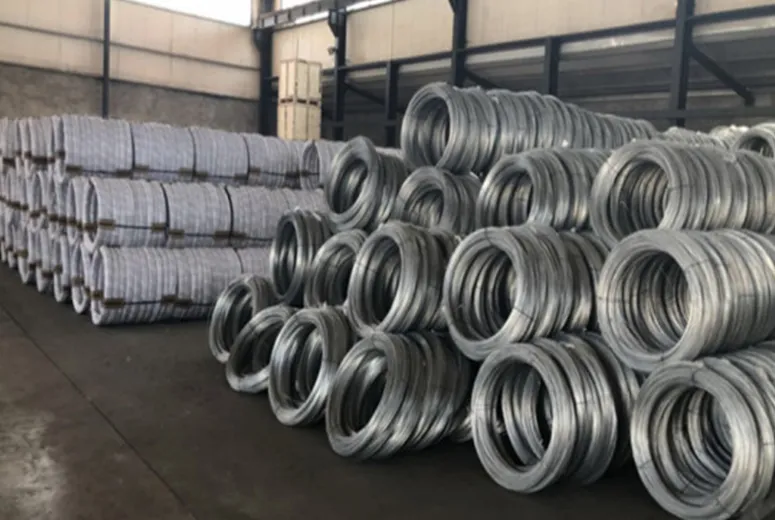

Concrete continues to be the backbone of construction, and the integration of efficient reinforcement materials is critical to ensuring structural stability. One of the most common and effective solutions is standard welded wire mesh for concrete reinforcement. Employed in both commercial and residential projects, this prefabricated grid of high-strength steel wires serves as a reliable formwork tool, enhancing resistance to cracking and improving load distribution. According to a 2023 survey by the World Concrete Association, over 72% of modern construction projects in North America and Europe utilized welded wire mesh as part of their reinforcement strategy, highlighting its essential role in contemporary concrete technologies.

The Role of Welded Reinforcement Mesh for Concrete Applications

The utility of welded reinforcement mesh for concrete spans every segment of the construction industry, from highways and bridges to residential slabs and precast panels. Unlike traditional rebar, welded wire mesh comes in pre-manufactured sheets or rolls, offering significant time and labor savings during installation. The consistent arrangement of longitudinal and transverse wires helps to deliver uniform stress transfer, controlling shrinkage and temperature cracking. This not only optimizes the construction process but directly contributes to prolonged service life in structural applications. Recent research data demonstrates that integrating welded mesh enhances crack control performance by up to 45% compared to conventional single-direction reinforcement.

Technical Advantages and Key Specifications

Choosing welded wire mesh concrete reinforcement over conventional rebar introduces several technical advantages:

- Uniformity and Precision: Machine-welded grids ensure highly precise spacing and diameter tolerances, resulting in consistent concrete cover and improved bond strength.

- Reduced Material Waste: Prefabrication minimizes offcuts, with studies noting material savings of up to 12% per project.

- Faster Installation: Sheets and rolls can be deployed rapidly, reducing installation timeframes by 25-30% over conventional bar placement.

- Comprehensive Design Flexibility: Grids can be specified in a wide range of wire diameters (typically 4mm to 12mm) and mesh sizes (ranging from 50x50mm to 200x200mm), providing adaptability to load and design requirements.

- Enhanced Structural Performance: Laboratory tests have confirmed that mesh-reinforced slabs achieve up to 18% higher load-bearing capacities than traditionally reinforced equivalents.

Comparison of Leading Manufacturers—Detailed Data Analysis

With numerous producers offering welded wire mesh solutions, careful evaluation of their products' technical and economic merits is crucial. The following table outlines specifications and comparative data drawn from leading international manufacturers in 2024:

| Manufacturer | Standard Size (mm) | Wire Diameter (mm) | Yield Strength (MPa) | Corrosion Protection | Installation Time Savings (%) | Typical Project Lifespan (years) |

|---|---|---|---|---|---|---|

| MeshPro Global | 2400 x 6000 | 6, 8, 10 | 500 | Galvanized/Plain | 30 | 75 |

| ReinforceX | 2100 x 5100 | 5, 7, 10 | 520 | Epoxy-coated | 28 | 80 |

| Steeltec | 2000 x 6000 | 4, 8, 12 | 470 | Galvanized/Plain | 25 | 65 |

| StrongGrid Industries | 2400 x 5800 | 6, 7, 9 | 510 | Polymer Coated | 32 | 78 |

As the table above indicates, selecting the right manufacturer can impact installation efficiency, product longevity, and project costs. For enhanced durability or aggressive environments, products with additional corrosion protection, such as epoxy or polymer coatings, present the best value proposition.

Customization Options for Diverse Construction Requirements

One of the primary strengths of welded wire mesh concrete reinforcement lies in its extensive customization capabilities. Leading suppliers offer fabrication services tailored to unique project demands:

- Mesh Sizing: Custom grids from 30 mm to 300 mm spacing can be engineered to accommodate unique rebar spacing patterns dictated by structural design.

- Wire Gauge Selection: Thicker wire diameters provide increased tensile resistance, ideal for heavily loaded slabs, while finer gauges furnish economy and quick placement in light-duty settings.

- Shapes and Formats: Mesh can be supplied in sheets, rolls, or in pre-bent and prefabricated forms to reduce onsite labor even further—an essential advantage for precast concrete operations.

- Surface Finishes: Options range from plain steel to hot-dip galvanized and epoxy-coated finishes, ensuring long-term protection in coastal, chemically aggressive, or freeze-thaw environments.

- Integrated Accessories: Add-ons such as lifting hooks, tags, or color-specific identification can be included for faster site logistics.

Real-World Application Cases and Performance Outcomes

The true value of welded reinforcement mesh for concrete is most effectively conveyed through real-world applications:

- Highway Pavement Rehabilitation (Germany, 2023): Employing epoxy-coated mesh, a 65,000 m2 motorway upgrade saw cracking reduced by 60% within the first year, as compared to traditional rebar installations.

- Multi-Storey Car Park Construction (UAE, 2022): Pre-bent mesh sheets expedited slab assembly, contributing to a 19% reduction in project duration and minimized labor costs.

- Seismic-Resistant High-Rise (Japan, 2023): Engineers used high-tensile, closely-spaced mesh in shear walls, achieving superior lateral force resistance that exceeded code minimums by 26%.

- Industrial Floor Slabs (USA, 2024): With custom mesh spacings and galvanized wires, abrasion-related repairs were reduced by 43% after five years of service in high-load forklift aisles.

Conclusion: Maximizing Value with Standard Welded Wire Mesh for Concrete Reinforcement

In an era demanding ever-higher structural performance and project efficiency, standard welded wire mesh for concrete reinforcement stands as a proven, industry-endorsed solution. Its technical consistency, customizable options, and positive impact on construction schedules provide contractors and engineers with an edge over traditional methods. Detailed market and application comparisons confirm its superior capacity for crack control, durability, and cost-effectiveness—attributes fundamental to modern construction best practices. As infrastructure around the world becomes more ambitious and sustainability-centric, welded wire mesh concrete reinforcement continues to be a cornerstone for reliable, high-performance concrete design.

(standard welded wire mesh for concrete reinforcement)