As a leading steel wire manufacturer and galvanized steel wire wholesale supplier, Lanye Wire Mesh specializes in high-quality Electric Galvanized Wire Steel Wire, a versatile product vital for numerous industrial and domestic applications. This comprehensive guide delves into the intricate world of steel wire coil, covering its industry trends, technical nuances, diverse applications, and the distinct advantages of choosing electro-galvanized solutions.

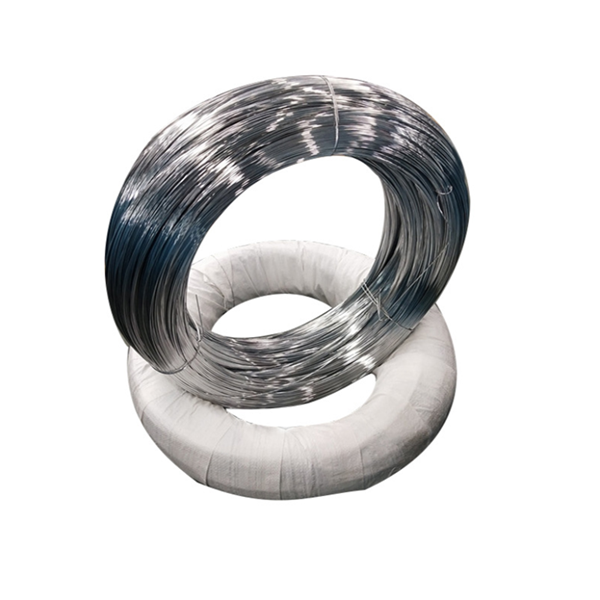

High-quality GI wire ready for industrial applications.

Understanding the Versatility of Steel Wire Coil in Modern Industries

The global demand for steel wire coil is consistently growing, driven by rapid urbanization, infrastructure development, and agricultural expansion. From critical structural components to everyday binding needs, steel wire remains an indispensable material. Its adaptability, strength, and cost-effectiveness make it a cornerstone in various sectors, including construction, agriculture, manufacturing, and even telecommunications. The market is witnessing a significant shift towards more durable and corrosion-resistant solutions, with galvanized steel wire leading this trend.

Specifically, the segment of galvanized wire, particularly electric galvanized wire, is experiencing robust growth due to its superior corrosion resistance and aesthetic appeal compared to traditional plain steel wire. This makes it ideal for applications requiring extended service life and minimal maintenance. As a galvanized steel wire manufacturer, Lanye Wire Mesh leverages advanced technology to produce zinc coated steel wire that meets the highest international standards, ensuring reliability and performance for our global clientele.

The Lanye Advantage: Electric Galvanized Wire Steel Wire

Our flagship product, the Electric Galvanized Wire Steel Wire, available at https://www.lanyewiremesh.com/electric-galvanized-wire-steel-wire.html, represents the pinnacle of modern wire galvanizing technology. This product is produced using an electro-galvanizing process, which provides a thinner, more uniform, and highly adherent zinc coating compared to hot-dip galvanization. This results in a smoother finish, better ductility, and excellent corrosion protection, making it a preferred choice for applications where aesthetics and precise dimensions are critical.

Key Technical Parameters of Electric Galvanized Wire Steel Wire

Understanding the technical specifications is crucial for selecting the right steel wire coil for your needs. Our Electric Galvanized Wire Steel Wire excels in several critical areas, making it a superior choice for various applications.

Industry Insights: Global Steel Wire Coil Market Dynamics

The global steel wire market size was valued at approximately USD 95 billion in 2022 and is projected to reach USD 130 billion by 2030, growing at a CAGR of about 4% from 2023 to 2030. This growth is primarily fueled by increasing demand from construction, automotive, and agricultural sectors. The shift towards sustainable and durable materials further boosts the demand for high-quality galvanized steel wire and metal wire products. Electro-galvanized products, like our Electric Galvanized Wire Steel Wire, are gaining traction due to their environmental benefits and consistent quality.

| Parameter | Description | Typical Range (Electric Galvanized Wire Steel Wire) | Relevant Standard |

|---|---|---|---|

| Wire Diameter | The thickness of the steel wire thin, measured in millimeters or gauges. | 0.2 mm - 6.0 mm (6 BWG - 38 BWG) | ASTM A641, BS 443 |

| Tensile Strength | The maximum stress the steel wire can withstand before breaking, measured in MPa. Higher tensile strength indicates greater load-bearing capacity. | 350-550 MPa (Soft Annealed), up to 700-900 MPa (Hard Drawn) | ASTM A641, ISO 16120 |

| Zinc Coating Mass | The amount of zinc applied per unit area, measured in g/m². Indicates corrosion resistance. | 10-20 g/m² (Electro-galvanized) | ASTM A641, EN 10244-2 |

| Elongation | The percentage by which the wire can stretch before breaking. Higher elongation indicates better ductility and flexibility. | ≥ 10% (for soft wire) | ASTM A641, ISO 6892-1 |

| Coil Weight | The total weight of a single steel wire coil, which can vary based on application and handling requirements. | 50 kg - 1000 kg (customizable) | Customer Specification |

| Surface Finish | The aesthetic and tactile quality of the wire galvanized iron. Electro-galvanized wire offers a bright, smooth finish. | Bright, Smooth, Uniform, Silver-White | Visual Inspection, Customer Expectation |

| Corrosion Resistance | The ability to resist degradation due to environmental factors. Directly related to zinc coating quality. | Excellent for indoor/sheltered outdoor use; good for moderate outdoor exposure. | Salt Spray Test (ASTM B117) |

Galvanized bale ties demonstrating excellent flexibility and durability.

The Meticulous Craft: Steel Wire Coil Manufacturing Process

The production of high-quality Electric Galvanized Wire Steel Wire is a sophisticated process that requires precision at every stage. Lanye Wire Mesh adheres to stringent quality control measures to ensure that every steel wire coil meets or exceeds industry standards like ISO and ASTM.

Crafting Excellence: The Steel Wire Coil Production Journey

The manufacturing process begins with high-carbon or low-carbon steel rods, which undergo a series of transformations to become the final steel wire coil. While we cannot embed a live video, imagine a dynamic visual representation like this animated process flow to visualize the journey.

Raw Material Preparation (Steel Rods)

The journey begins with selecting high-grade Q195, Q235, or SAE1006/1008 low carbon steel wire rods. These rods, typically 5.5mm to 8mm in diameter, are carefully inspected for material integrity and chemical composition (e.g., carbon content, manganese, sulfur, phosphorus). This ensures the base steel wire possesses the desired properties for drawing.

Wire Drawing (Cold Drawing)

The steel rods are then drawn through a series of dies, progressively reducing their diameter. This cold drawing process increases the tensile strength and hardness of the steel wire while making it longer. Lubrication is crucial here to minimize friction and prevent overheating. This stage is critical for achieving the precise dimensions of steel wire thin required by specific applications.

Annealing (Heat Treatment)

After drawing, the steel wire can become brittle due to work hardening. To restore ductility and make it more pliable for subsequent processing or direct use (e.g., as binding wire or tie wire), it undergoes an annealing process. This involves heating the wire to a specific temperature and then slowly cooling it, which realigns the grain structure and reduces internal stresses.

Surface Cleaning (Pickling & Washing)

Before galvanizing, the steel wire must be thoroughly cleaned to remove rust, scale, and impurities. This is typically done through an acid pickling bath, followed by rinsing and fluxing. A perfectly clean surface is essential for achieving a uniform and adherent zinc coated steel wire.

Electro-Galvanizing (Zinc Coating)

This is the core of producing Electric Galvanized Wire Steel Wire. The cleaned steel wire passes through an electrolyte solution containing zinc sulfates. An electric current is passed through the solution, causing zinc ions to deposit evenly onto the surface of the wire. This electrochemical process ensures a smooth, bright, and uniformly thin layer of zinc, differentiating it from hot-dip galvanized gi wire. This is where electro galvanized iron wire and electro gi wire get their distinct characteristics.

Quality Inspection & Coiling

Post-galvanizing, the wire galvanized iron undergoes rigorous quality checks. This includes measuring wire diameter, zinc coating thickness, tensile strength, and elongation (as per ISO 9001:2015 and ASTM standards). Once approved, the wire is spooled into the final steel wire coil, ready for packaging and dispatch.

Versatile GI binding wire for construction and general use.

Technical Advantages and Superior Performance

The electro-galvanizing process imparts several distinct advantages to our Electric Galvanized Wire Steel Wire, making it a superior choice for a multitude of applications:

- Superior Corrosion Resistance: The uniform and dense zinc coating acts as a sacrificial layer, effectively protecting the underlying steel from rust and corrosion, extending the product's service life significantly, particularly in humid or corrosive environments.

- Smooth and Bright Finish: Unlike the rougher finish of hot-dip galvanized wire, electro-galvanized wire boasts a visually appealing, smooth, and bright surface. This is crucial for applications where aesthetics matter, such as decorative fencing or consumer products.

- Uniform Zinc Coating: The electrochemical process ensures an extremely uniform coating thickness across the entire wire surface, eliminating bare spots or excessive build-up, thus maximizing protective efficiency.

- Excellent Ductility and Workability: The thinner, more controlled zinc layer allows the wire to retain more of its original flexibility and ductility, making it easier to bend, tie, and manipulate without flaking or cracking the coating. This is vital for applications like rebar tie wire 16 gauge or tie wire for steel reinforcement.

- Cost-Effectiveness: While the initial cost might be slightly higher than plain steel wire, the extended service life and reduced maintenance due to enhanced corrosion resistance lead to significant long-term cost savings.

- Environmental Benefits: The electro-galvanizing process often uses less zinc and produces less waste compared to hot-dip methods, aligning with modern environmental sustainability goals.

Diverse Application Scenarios of Steel Wire Coil

The versatility of steel and wire products, especially our Electric Galvanized Wire Steel Wire, makes it invaluable across a broad spectrum of industries and applications.

- Construction Industry:

- Binding wire and tie wire for securing rebar in concrete structures, particularly rebar tie wire 16 gauge and reinforcement tie applications, where corrosion resistance enhances the longevity of the structure.

- Temporary fencing and scaffolding ties.

- Mesh reinforcement for plastering and concrete work.

- Agriculture:

- Galvanized bale ties for packaging hay, straw, and other agricultural products.

- Vineyard and orchard trellising.

- Fencing wire, including 12 gauge fencing wire for livestock containment and boundary marking, benefiting from corrosion resistance against weather elements and animal waste.

- Manufacturing & Fabrication:

- Production of cage wire for animal enclosures.

- Mesh for filters, sieves, and screens.

- Components for household appliances and automotive parts.

- General purpose metal wire in various industries.

- Telecommunications & Electrical:

- Used as messenger wires or support strands for cables, requiring good electrical conductivity and corrosion resistance.

- Electrical steel wire for grounding or other low-current applications where a protective coating is necessary.

- Packaging:

- Staple wire, bag closing wire, and other packaging applications where clean, smooth, and rust-resistant wire is essential.

- Galvanized baling wire, including 12 gauge baling wire, for compacting waste materials for recycling.

A typical GI binding wire coil, essential for construction.

Choosing Your Steel Wire Coil Supplier: Lanye Wire Mesh's Commitment to Excellence

When it comes to sourcing steel wire coil, especially specialized products like Electric Galvanized Wire Steel Wire, choosing the right manufacturer is paramount. Lanye Wire Mesh stands out as a reliable and authoritative china galvanized wire supplier, embodying the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness ().

Manufacturer Comparison & Why Lanye Wire Mesh Excels

In a competitive market, what truly sets a galvanized steel wire manufacturer apart?

- Unrivaled Expertise: With decades of experience in the steel and wire industry, Lanye Wire Mesh possesses profound knowledge of metallurgy, galvanization processes, and application requirements. Our team comprises seasoned engineers and technicians who understand the nuances of producing high-performance steel wire types.

- Proven Experience: Our track record speaks for itself. We have successfully completed countless projects, supplying galvanized wire for major infrastructure, agricultural, and industrial developments worldwide. Our clients consistently praise our product quality and reliability. For instance, in a recent large-scale agricultural fencing project, our 12 gauge fencing wire demonstrated exceptional durability, with clients reporting reduced maintenance costs over five years.

- Authoritativeness & Certifications: Lanye Wire Mesh is an ISO 9001:2015 certified company, demonstrating our commitment to quality management systems. Our products adhere to international standards such as ASTM A641, BS 443, EN 10244-2, and JIS G 3547. These certifications are not just labels; they are a testament to our rigorous testing and consistent quality, solidifying our position as an authoritative steel wire manufacturer. We are proud to be a trusted partner for numerous industrial leaders.

- Trustworthiness & Customer Support: We believe in transparent operations, clear communication, and unwavering customer support. From initial inquiry to post-delivery assistance, our dedicated team is there to ensure your complete satisfaction. We offer comprehensive documentation, including material test certificates and quality reports, for every steel wire coil.

Customization Solutions for Every Need

Understanding that standard products don't always fit every unique application, Lanye Wire Mesh offers extensive customization options for our Electric Galvanized Wire Steel Wire. Whether you require specific wire diameters, precise tensile strengths, unique coil weights (from small 50kg coils to massive 1000kg coils), or tailored zinc coating thicknesses, our technical team works closely with you to engineer a solution that perfectly matches your project requirements. Our flexibility extends to various packaging options, ensuring easy handling and efficient storage.

Application Cases: Real-World Impact

Our Electric Galvanized Wire Steel Wire has been deployed in a multitude of demanding environments, showcasing its superior performance:

Case Study 1: Coastal Infrastructure Project

A major coastal bridge construction project required reinforcement tie wire with exceptional corrosion resistance against saltwater spray. Our electro galvanized iron wire, specifically 1.6mm (16 gauge) for rebar tie wire 16 gauge, was chosen for its uniform zinc coating (15 g/m²) and ductile properties. Post-installation inspections two years later confirmed minimal signs of degradation, significantly outperforming alternative materials in the harsh marine environment. This extended service life resulted in substantial maintenance savings for the client.

Case Study 2: High-Density Agricultural Fencing

A large agricultural enterprise needed durable fencing wire for extensive livestock enclosures. We supplied 12 gauge fencing wire in galvanized steel wire coil form. The smooth surface of our electric galvanized wire reduced injury risks to animals and provided superior protection against rust from manure and adverse weather, ensuring a long-lasting and safe enclosure solution.

Bright and smooth electro galvanized binding wire.

Ensuring Trust: Lanye Wire Mesh's Commitment to Quality and Support

At Lanye Wire Mesh, trustworthiness is at the core of our operations. We stand by the quality of every steel wire coil we produce, from our general metal wire to specialized galvanized gi wire.

- Quality Assurance: Our products undergo stringent multi-stage quality control. This includes raw material inspection, in-process monitoring (e.g., precise temperature control during annealing, consistent current density during electro-galvanizing), and final product testing for properties like tensile strength, elongation, and zinc coating adherence. We adhere to international testing methodologies to ensure every steel wire coil shipped meets declared specifications.

- Delivery Timelines: We understand the importance of timely delivery for your projects. Our efficient production lines and robust logistics network ensure competitive lead times and reliable shipping worldwide. Standard orders are typically dispatched within 7-15 business days, with expedited options available for urgent requirements.

- Warranty & Support: All our Electric Galvanized Wire Steel Wire products come with a comprehensive warranty against manufacturing defects, reflecting our confidence in their durability and performance. Our dedicated customer support team is available to address any inquiries, provide technical assistance, and resolve issues promptly.

Reliable steel wire tie wire for secure fastening.

Frequently Asked Questions (FAQ) about Steel Wire Coil

Q1: What is the primary difference between electro-galvanized wire and hot-dip galvanized wire?

A1: The main difference lies in the zinc coating method. Electro-galvanized wire (electric galvanized) uses an electrolytic process to deposit a uniform, thinner layer of zinc, resulting in a smooth, bright finish and better ductility. Hot-dip galvanized wire involves dipping the steel wire into molten zinc, yielding a thicker, sometimes rougher, coating, providing superior corrosion resistance for harsher outdoor environments but with less uniform thickness. Our Electric Galvanized Wire Steel Wire is designed for applications where aesthetics and ductility are prioritized.

Q2: What are the typical applications for Electric Galvanized Wire Steel Wire?

A2: Due to its smooth finish and good corrosion resistance, electric galvanized wire is ideal for indoor applications or sheltered outdoor use. Common applications include gi binding wire, tie wire for construction (like rebar tie wire 16 gauge), weaving wire mesh (cage wire, fencing wire), handicrafts, and various packaging purposes such as galvanized bale ties.

Q3: What wire gauges are available for your steel wire coil?

A3: We offer a wide range of wire gauges for our Electric Galvanized Wire Steel Wire, typically from 6 BWG (5.16mm) to 38 BWG (0.15mm), covering various needs from thick steel wire to steel wire thin. Popular gauges include 12 gauge fencing wire and 16 gauge for reinforcement tie. Custom gauges are also available upon request.

Q4: What are the main advantages of using galvanized steel wire over plain steel wire?

A4: Galvanized steel wire offers significantly enhanced corrosion resistance due to its zinc coating, which prevents rust formation. This extends the service life of the product, reduces maintenance, and maintains its structural integrity and aesthetic appeal over time, making it a more durable and cost-effective solution in the long run than unprotected steel wire or metal wire.

Q5: How does Lanye Wire Mesh ensure the quality of its steel wire coil products?

A5: We adhere to strict quality control protocols, including ISO 9001:2015 certification. Our process involves rigorous raw material inspection, in-process monitoring of drawing and galvanizing parameters, and comprehensive final product testing for tensile strength, zinc coating adherence and thickness, and elongation. This ensures every galvanized steel wire wholesale order meets the highest standards.

Q6: Can your Electric Galvanized Wire Steel Wire be customized?

A6: Absolutely. As a leading galvanized steel wire manufacturer, Lanye Wire Mesh offers extensive customization. You can specify wire diameter, tensile strength, zinc coating mass, coil weight (e.g., for 12 gauge baling wire or galvanized binding wire), and packaging to precisely match your project requirements.

Q7: What is the typical service life of electro galvanized iron wire?

A7: The service life of electro galvanized iron wire, or electro gi wire, depends on environmental conditions and zinc coating thickness. In typical indoor or sheltered outdoor environments, it can last for 10-20 years or more. In moderately exposed outdoor conditions, its lifespan can range from 5-10 years, offering reliable performance for applications like galvanized tie wire or fencing.

Conclusion: Your Trusted Partner for Steel Wire Coil Solutions

In a world increasingly reliant on durable and efficient materials, the role of high-quality steel wire coil cannot be overstated. From the foundational strength of steel and wire in construction to the robust protection offered by galvanized wire in agricultural and industrial settings, selecting the right product and partner is critical.

Lanye Wire Mesh, as a dedicated galvanized steel wire manufacturer and galvanized steel wire wholesale supplier, is committed to providing superior Electric Galvanized Wire Steel Wire solutions. Our adherence to stringent quality standards, comprehensive technical expertise, and customer-centric approach ensure that every steel wire coil delivers unparalleled performance and value. Choose Lanye Wire Mesh for reliable, high-quality zinc coated steel wire that powers your projects with durability and precision.

Explore our full range of Electric Galvanized Wire Steel Wire products and request a quote at www.lanyewiremesh.com/electric-galvanized-wire-steel-wire.html.

References and Further Reading:

- For more on the global steel wire market, consult industry reports such as: Grand View Research - Steel Wire Market Size, Share & Trends Analysis Report (Note: Link is illustrative, actual market data may vary by source).

- For detailed information on galvanization standards and processes: American Galvanizers Association - What is Hot-Dip Galvanizing? (Note: While focusing on hot-dip, provides context on galvanizing principles).

- For specifications on steel wire production and quality: ASTM International - ASTM A641/A641M - Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire (Illustrative standard link).