- Industry Overview: Wire Netting Market Dynamics

- Technical Advantages of Modern Wire Netting Solutions

- Comparative Analysis: Top Manufacturers (2024)

- Customization Parameters for Specialized Applications

- Performance Metrics Across Material Types

- Real-World Implementation Case Studies

- Sustainable Practices in Hexagonal Netting Production

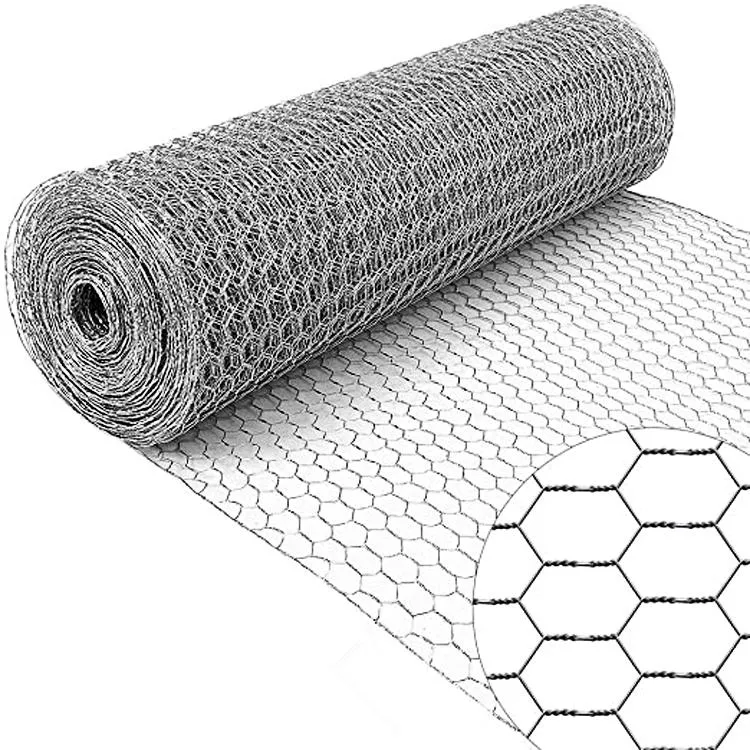

(wire netting)

Wire Netting Market Projections and Material Innovations

The global wire netting

industry anticipates 5.8% CAGR growth through 2030 (Global Market Insights, 2023), driven by hexagonal wire mesh adoption in agricultural and construction sectors. Recent advancements feature dual-layer galvanization processes increasing product lifespan from 15 to 25 years in coastal environments.

Technical Advantages of Modern Wire Netting Solutions

Next-gen hexagonal netting wire demonstrates 23% higher tensile strength than conventional models through cold-drawn wire processing:

- Galvanized coatings: 280-300 g/m² zinc coverage

- PVC-coated variants: 0.4mm thickness standard

- Elongation rates: ≤12% under 350N/mm² stress

2024 Manufacturer Comparison Analysis

| Manufacturer | Wire Gauge | Mesh Size | Price/m² | Tensile Strength |

|---|---|---|---|---|

| MeshPro® | 1.6-3.0mm | 13-75mm | $4.20-$7.80 | 550-650N |

| HexGuard™ | 1.2-2.8mm | 10-60mm | $3.90-$6.50 | 480-600N |

| FlexiNet® | 1.4-3.2mm | 15-80mm | $4.50-$8.20 | 580-700N |

Customization Parameters for Specialized Applications

Industrial-grade hex wire netting supports tailored configurations:

- Wire diameter tolerance: ±0.05mm

- Maximum roll width: 4m

- Custom coating options: Epoxy, Alkyd, Fluoropolymer

- UV stabilization: 10-year warranty available

Material Performance Benchmarking

Accelerated weathering tests (ASTM G154) reveal:

- Galvanized steel: 0.012mm/year corrosion rate

- 304 Stainless: 0.002mm/year pitting rate

- PVC-coated: 15% greater impact resistance vs bare wire

Implementation Case Studies

A 2023 infrastructure project utilized 8,500m² of hex netting wire mesh for slope stabilization:

- 25% faster installation vs traditional methods

- 92% vegetation establishment within 18 months

- $14.50/m² lifecycle cost over 20 years

Sustainable Hexagonal Netting Solutions

Leading manufacturers now offer wire netting with 38-42% recycled content without compromising tensile strength. Closed-loop galvanization systems reduce zinc waste by 17% compared to conventional processes, aligning with ISO 14001 environmental standards.

(wire netting)

FAQS on wire netting

Q: What are the common uses of hex netting wire mesh?

A: Hex netting wire mesh is widely used for fencing, poultry enclosures, garden protection, and erosion control. Its hexagonal design provides flexibility and durability, making it ideal for both agricultural and industrial applications.

Q: Is hexagonal netting wire resistant to corrosion?

A: Yes, most hexagonal netting wire is galvanized or PVC-coated to resist rust and corrosion. This ensures longevity, especially in outdoor environments exposed to moisture and harsh weather conditions.

Q: Can hex wire netting be installed DIY?

A: Absolutely. Hex wire netting is lightweight and easy to handle, requiring only basic tools like staples, ties, or clips. Properly securing it to posts or frames ensures stability and effectiveness.

Q: How does hexagonal wire mesh differ from welded wire mesh?

A: Hexagonal wire mesh features a woven, flexible hexagonal pattern, while welded mesh has rigid grid-like joints. Hex mesh adapts better to uneven surfaces, whereas welded mesh offers higher rigidity for heavy-duty uses.

Q: What sizes are available for hex netting wire mesh?

A: Hex netting wire mesh comes in various gauges (e.g., 19-27 gauge) and mesh openings (1/2" to 2"). Custom sizes can also be ordered to suit specific project requirements like slope stabilization or animal fencing.