Black Annealed Rewound Wire Coils

-Wire diameter : 0.9-5.5mm

-Coil weight : 500kg-1000kg/coilOnly one thread in the whole coil

-The process of using the wire is from the top of the roll all the way to the bottom, not the outer ring to the inner ring.

The main wire material is low carbon steel wire.

Black annealed wire offers excellent flexibility and softness due to its oxygen-free annealing process.

Black annealed wire material is normally provided by the Q195 type drawing rod into the black wire.The selected raw materials after 1000 degrees high temperature calcination keep enough time, then to appropriate cooling rate.The purpose is to reduce the hardness, improved machinability; elimination of residual stress, stable size, reduce the deformation and crack tendency; grain refinement, restructuring the organization, eliminate defects in the organization.

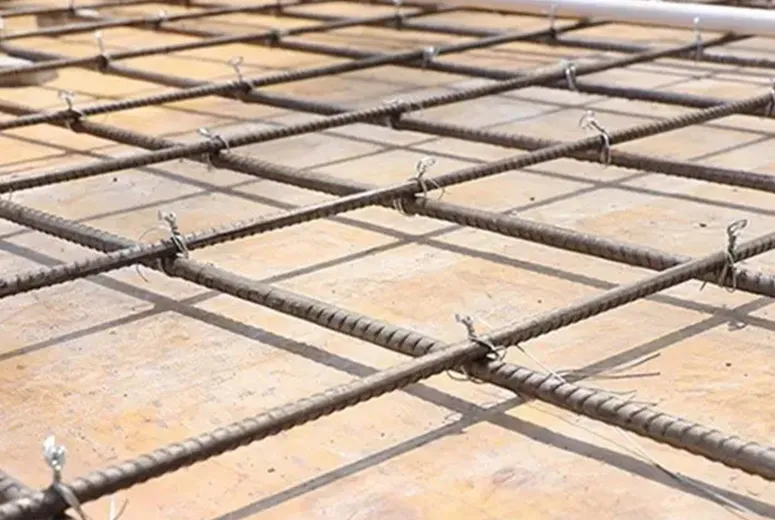

Black Annealed Wire is mainly processed into coil wire, spool wire or big package wire. Annealed wire is used as tie wire or baling wire in building, parks and daily binding. Besides, black annealed wire is mainly used as industrial wire, construction wire, industrial bale tie wire and constructional tie wire, etc.

What Is the Production Basis for Black Annealed Wire?

The production starts with Q195 steel wire as the raw material. As a black annealed wire manufacturer, Dingzhou Lanye Metal Products Co., Ltd. processes Q195 through controlled drawing to required diameters, then subjects the strands to high-temperature calcination at about 1000 degrees for sufficient dwell time to release internal stresses and homogenize microstructure. After calcination the material is cooled at an appropriate cooling rate to achieve the soft, ductile condition characteristic of annealed wire. For buyers this means the delivered black steel wire will show consistent elongation, bendability, and surface blackening suitable for tying, binding, and forming operations. Quality checkpoints include incoming material identity (Q195 certification), visual surface inspection after annealing, and mechanical checks focused on ductility rather than tensile peak values, matching typical buyer performance expectations for annealed black wire.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.