PVC Coated Steel Wire

-Material: Q195 Low Carbon steel wire

Surface: PVC Coated

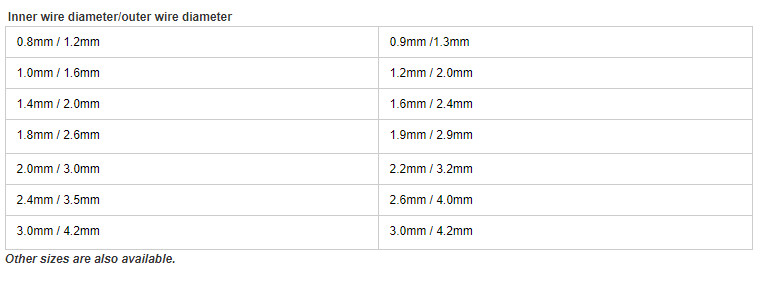

Wire diameter: 0.5mm-4.5mm

Weight: 1kg,5kg,25kg,50kg,800kg

Package: Plastic inside,woven bag outside

Usage: binding wire

Port of loading: Xingang,China

Place of Origin: Hebei,China

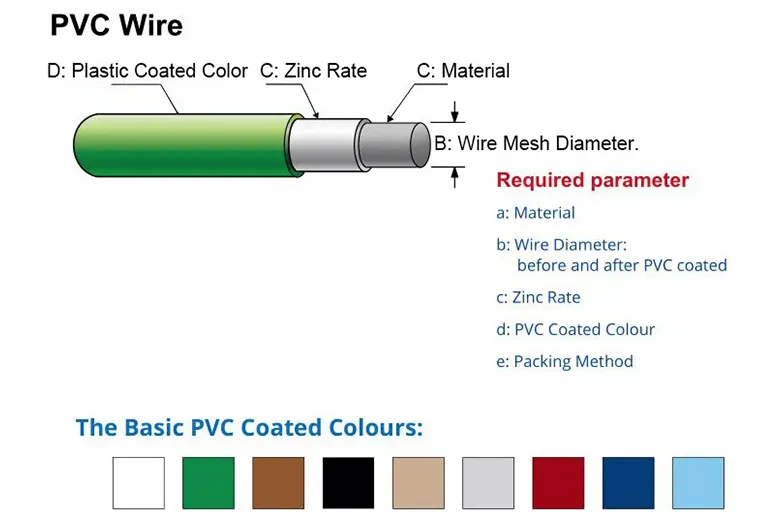

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires.

The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics.

-The product uses high-quality galvanized wire or annealed wire as raw material, and after deep processing, the PVC and the wire are firmly connected.

-Plastic wire varieties: mainly including black wire plastic wire, galvanized wire plastic wire, stainless steel wire plastic wire, copper wire plastic wire, etc.

-The plastic coated wire can add extra anti ultraviolet and anti-aging auxiliaries to extend the service life.

-Service life of plastic coated wire: high density original plastic, surface water absorption is 0, resistant to common acid and alkali, service life up to 12 years.

It is widely used in animal breeding, agriculture and forestry protection, aquaculture, park, zoo fence, stadium and daily life,etc.

Plastic coated wire is used in manufacturing of binding wire, tie wire, plant support wire, meshes and fences.

How Does Pvc Coated Steel Wire Perform in Harsh Environments?

PVC Coated Steel Wire is specifically engineered for performance under challenging conditions. The tightly bonded PVC layer acts as a barrier against chemical exposure, moisture, and UV radiation, significantly extending the wire’s lifespan. This makes it suitable for outdoor use, including fencing, landscaping, and reinforced structures where environmental stress could otherwise accelerate wear. Its anti-aging and anti-corrosion properties are particularly valuable for coastal or industrial locations where humidity or chemical exposure is high. Additionally, the anti-cracking nature of the coating maintains flexibility, preventing the wire from breaking during installation or under mechanical stress. By selecting PVC Coated Steel Wire from Dingzhou Lanye Metal Products Co., Ltd., buyers ensure that the product will consistently meet functional and safety requirements over time, reducing replacement frequency and operational costs.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.