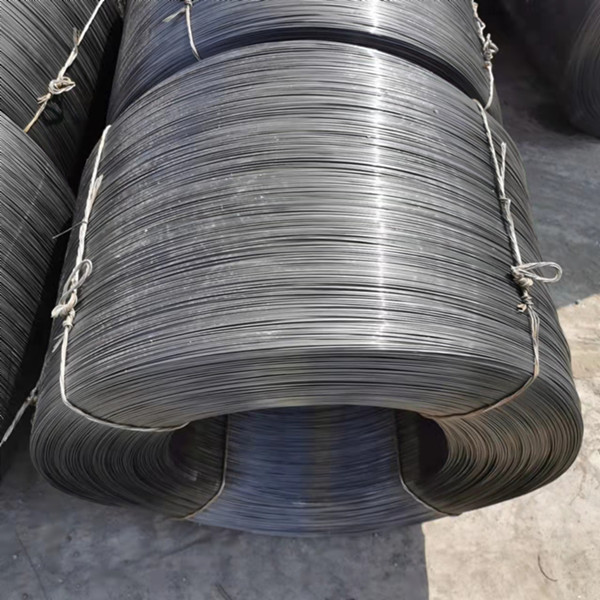

Cold-Drawn Black Bright Hard Wire

-Material: Q195 Low Carbon steel wire

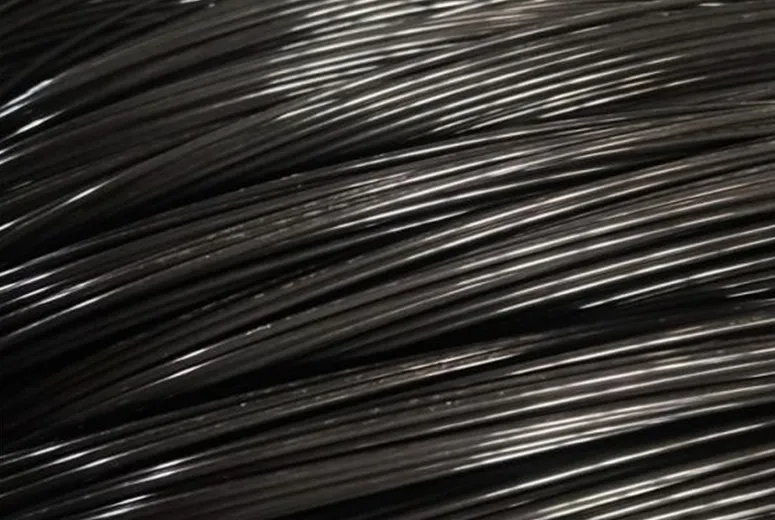

-Surface: Bright

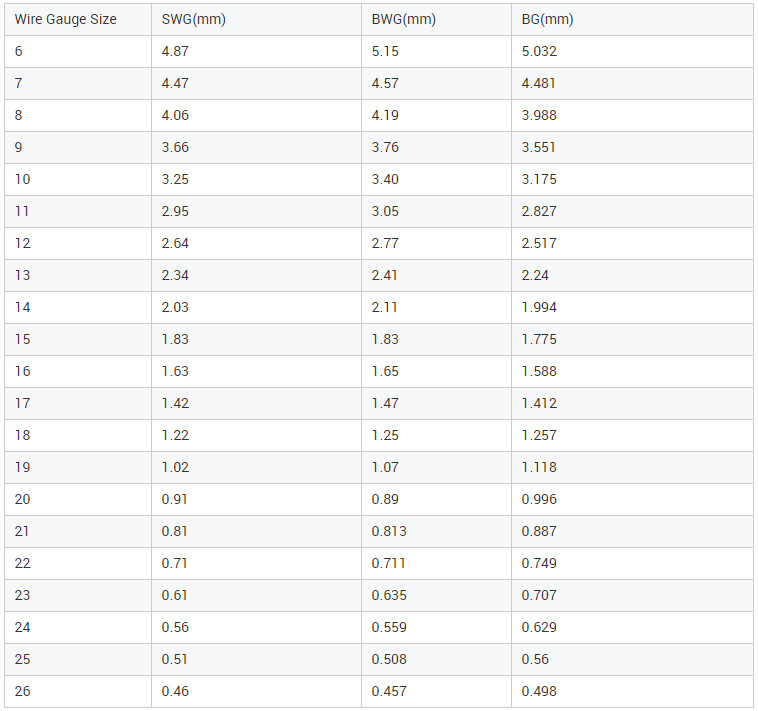

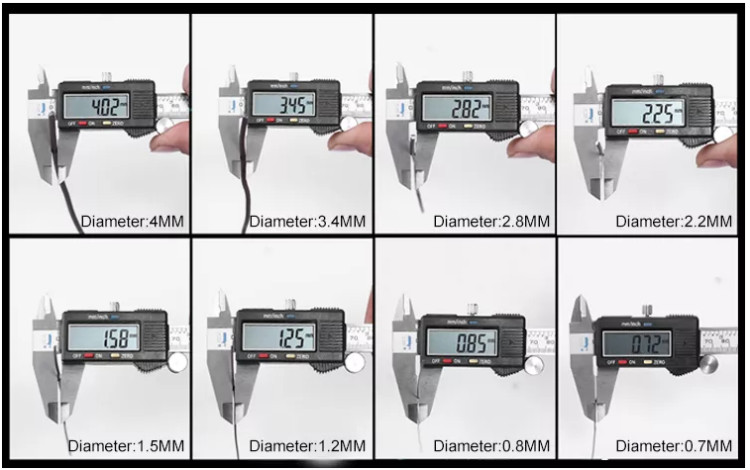

-Wire diameter: 0.7mm-5.0mm

-Weight:700-1000kg/coil

-Package: plastic inside,woven bag outside

-Port of loading: Xingang,China

-Place of Origin: Hebei,China

Cold-drawn black bright hard wire is an unannealed wire with hard material.

It is used as raw material for nail making, welded wire mesh panels, or continues to be further processed into other products.

How Does Cold-Drawn Black Bright Hard Wire Perform in Industrial Applications?

Cold-Drawn Black Bright Hard Wire demonstrates superior tensile strength and hardness due to the cold-drawing process applied to Q195 low carbon steel wire. The bright surface reduces surface defects and ensures smooth contact in automated machinery or coiling equipment, enhancing the precision of formed components. Its diameter flexibility from 0.7mm to 5.0mm allows adaptation to applications such as springs, nails, screws, and wire components in automotive, construction, and general manufacturing industries. The coil weight of 700–1000kg supports continuous production runs, reducing downtime from frequent coil changes. Buyers can rely on this wire for consistent dimensional accuracy and high functional stability, which are essential for maintaining quality standards in assembly lines.

Why Should Buyers Choose Dingzhou Lanye Metal Products Co., Ltd. For Cold-Drawn Black Bright Hard Wire?

Dingzhou Lanye Metal Products Co., Ltd. specializes in Cold-Drawn Black Bright Hard Wire with strict quality control and adherence to industrial standards. Using Q195 low carbon steel wire, the company ensures mechanical reliability and surface uniformity, meeting the needs of professional buyers. The product range covers diameters from 0.7mm to 5.0mm and coil weights of 700–1000kg, which suits both small-scale and large-scale operations. Their manufacturing process guarantees a bright, defect-free surface, which reduces post-processing requirements and improves efficiency in industrial applications. By choosing Dingzhou Lanye, buyers benefit from stable supply, technical support, and consistent wire performance, making it a preferred option for enterprises seeking durable, high-quality hard wire for critical applications.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.