Cold-Drawn Bright Wire Nail Wire

-

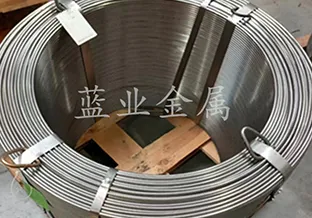

Nail Wire Roll

-

Wire for nail making

-

Wire for nail making

-

Nail Making Wire

What are the specifications of Cold-Drawn Bright Wire Nail Wire from Dingzhou Lanye Metal Products Co., Ltd.?

The Cold-Drawn Bright Wire Nail Wire supplied by Dingzhou Lanye Metal Products Co., Ltd. is made from low carbon steel wire, offering reliable mechanical performance and surface quality. Wire diameters range from 3.0 to 5.0mm, providing versatility for different nail production requirements. Each coil has a weight between 500-1000kg, which is suitable for large-scale industrial use. The product is designed for optimal handling, with usage recommended from the outer ring to the inner ring, rather than top to bottom, to maintain wire integrity and prevent deformation. The cold-drawn manufacturing process ensures a smooth, bright surface that enhances nail formation, reduces surface defects, and improves machinability. Buyers can rely on these specifications to ensure consistent quality for their production lines.

How Should Cold-Drawn Bright Wire Nail Wire Be Used Efficiently?

For effective utilization, the Cold-Drawn Bright Wire Nail Wire should be unwound from the outer ring to the inner ring. This practice minimizes coil stress and reduces the risk of wire tangling or surface damage. The low carbon steel wire composition ensures flexibility and uniform tensile strength, supporting continuous nail production without frequent breaks. Handling the coil according to this method maximizes the functional lifespan of the wire while maintaining consistent diameter quality between 3.0-5.0mm. Each 500-1000kg coil allows for extended machine run times, reducing downtime and improving production efficiency. Using the wire properly ensures that nail manufacturers achieve uniform nail heads, smooth shanks, and consistent lengths, all essential for high-quality end products.